ERP Integration Guide: Improving Supplier Performance

.png?width=50&height=50&name=julie-miller-square%20(1).png)

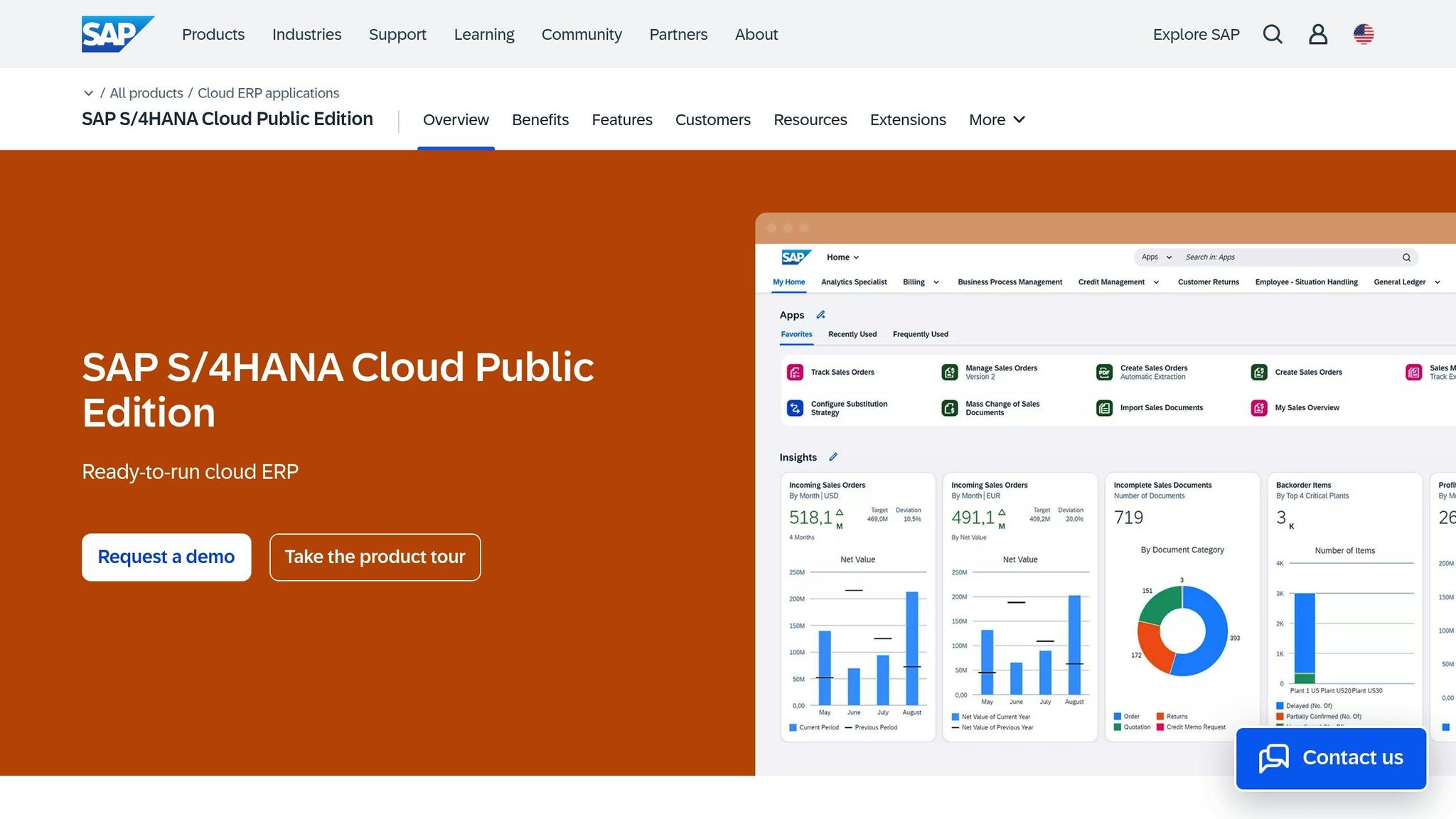

ERP systems can transform how you work with suppliers, improving communication, efficiency, and performance. Here’s how they help:

- Streamlined Communication: Consolidate all supplier interactions in one platform, reducing delays and miscommunication.

- Automation: Automate tasks like order approvals, invoicing, and compliance to save time and reduce errors.

- Real-Time Insights: Monitor supplier performance with live data on delivery accuracy, quality, and costs.

- Centralized Data: Create a unified supplier database to eliminate errors and improve collaboration.

- Supplier Portals: Provide suppliers with secure, real-time access to updates like order status and inventory.

- Performance Tracking: Use dashboards, scorecards, and automated alerts to address issues proactively.

Key Benefits:

- 15% improvement in on-time deliveries.

- 20% boost in operational efficiency.

- 30% fewer manual errors.

- $12.9 million saved annually by reducing data inaccuracies.

ERP systems help you go from reactive problem-solving to proactive supplier management, building stronger partnerships and driving better results.

SAP S/4HANA Ariba Upstream and Downstream with CIG Full Course | ZaranTech

Setting Up Centralized Supplier Data Management

To manage supplier performance effectively, the first step is consolidating all supplier data into one accessible system. A centralized database eliminates blind spots and ensures everyone in the organization is working with the same, up-to-date information. ERP systems are particularly useful for this, as they break down data silos and provide real-time updates.

The cost of inaccurate supplier data is staggering. Businesses lose an average of $12.9 million annually because of errors in supplier information. Only 13% of companies consider themselves leaders in supplier management, and nearly half of these leaders cite inefficient systems as a key challenge to better collaboration with suppliers.

Creating a Unified Supplier Database

Building a centralized supplier database isn’t just about gathering data - it’s about doing it strategically. Start by setting clear goals, such as improving visibility, compliance, or cost management. Then, standardize critical data points like supplier details, certifications, pricing, performance metrics, and risk assessments. This consistency ensures smoother operations and better supplier engagement across the board.

A great example of this approach comes from a North American beverage distributor. By consolidating five ERP systems using Informatica Supplier 360, they cut onboarding times by 50% and improved data quality with Dun & Bradstreet Enrichment.

Data mapping is another crucial step, especially for companies operating across multiple regions. Financial data from different locations must be translated into a unified master dataset. Before mapping, clean up existing data to fix errors and fill in gaps. This upfront effort can save significant time and prevent future issues.

Vendor master data management (MDM) systems are essential for maintaining a unified database. These systems ensure that all supplier information is accurate and consistent at its source, giving your entire organization access to reliable data.

| Data Category | Key Information |

|---|---|

| Business Profile Data | Supplier contact details, certifications, product offerings, references, and contracts |

| Performance Data | Metrics like delivery reliability, product quality, service quality, and contract compliance |

| Risk Management Data | Financial health, supply chain vulnerabilities, ESG compliance, and geopolitical risks |

With accurate, centralized data in place, you can take the next step: streamlining direct communication with your suppliers.

Setting Up Supplier Portals for Direct Communication

Supplier portals are a game-changer for secure, direct communication with supply chain partners. By eliminating third-party intermediaries, these portals simplify interactions and boost efficiency.

The best supplier portals combine centralized data access, automated workflows, performance monitoring, and financial integration. They allow suppliers to check real-time updates on inventory, orders, and delivery schedules. These features not only improve performance tracking but also hold suppliers accountable.

Take Verallia Group as an example. Using Ivalua’s supplier portal, they achieved full visibility into vendor data and centralized their supplier master data. The intuitive interface led to high adoption rates, streamlined their RFQ process, and created a centralized database for purchasing contracts.

"With Ivalua we finally have 360 degree visibility of suppliers and contracts and automate the full source-to-pay process in a system our users enjoy using." - Cyrille Chouvet, Supplier Quality & Purchasing Process Manager, Verallia Group

When implementing a supplier portal, focus on scalability, security, user experience, and integration. A seamless connection with your existing ERP, procurement, and financial systems is critical to avoid creating new silos. A user-friendly design encourages adoption and reduces the need for extensive training.

However, many companies still struggle to meet expectations with their portals. About 43% of businesses report that their onboarding portals fall short, often due to poor planning and lack of integration. For a company with $5 billion in annual spending, supplier onboarding can cost over $1 million per year in labor alone.

Security is another key advantage of supplier portals. They reduce fraud risks and provide direct control over sensitive financial and operational data. Unlike networks involving third parties in the payment process, portals maintain a direct relationship between buyers and suppliers.

"We should think about supplier onboarding as laying the foundations for what you might think of as world-class supplier management." - Anthony Payne, CMO at HICX

To maximize the portal’s effectiveness, invest in comprehensive training for both your team and your suppliers. Offer clear documentation, regular training sessions, and best practices for portal use. With 82% of organizations now incorporating supplier risk assessments into their data management, portals with risk-tracking capabilities are becoming essential.

Automating Core Procurement Processes

Handling procurement manually can be both expensive and prone to mistakes. In fact, in 2022, 36% of manufacturers globally turned to purchase order automation to cut costs and improve efficiency. Companies that use integrated operating models have reported slashing the costs of ordering materials and services by as much as 52%. By automating these essential procurement tasks, businesses can eliminate bottlenecks and avoid unnecessary delays.

"ERP Purchase Order Automation integrates the creation, submission, and management of purchase orders into an enterprise resource planning (ERP) system to optimize workflows and maximize efficiency." - Versa Cloud ERP

The secret to successful automation lies in configuring your ERP system to handle repetitive tasks while reserving critical decisions for your team. This approach allows your staff to focus on building strategic supplier relationships rather than getting bogged down in administrative work.

Automating Purchase Order Creation and Approval

Creating and approving purchase orders is often one of the most time-intensive tasks in procurement. Automation changes this by turning it into a smooth, efficient process. ERP systems can automatically generate purchase orders based on inventory levels, approved requisitions, and predefined business rules.

Take Coast Flight Training as an example. They used ProcureDesk to automate procurement across multiple locations in California and Texas. Their system introduced centralized digital requisitions, automated approval workflows, real-time budget tracking, and vendor catalog integration. The results? A 50% reduction in processing time (from seven days to just two or three), complete visibility into spending, better budget compliance, and standardized purchasing policies across the company.

"Automating the purchase order process transforms procurement from a time-consuming, error-prone task into a streamlined, intelligent workflow." - IBM

To get started with purchase order automation, you’ll need to establish clear rules for spending limits, approval hierarchies, and vendor selection. Configure your ERP system to enforce these rules automatically. A digital requisition system can allow employees to submit requests through standardized forms, which are then routed to the right approvers based on criteria like dollar amounts, department budgets, or product categories.

Once approvals are in place, standardized templates can auto-generate purchase orders that include key details like vendor information, delivery addresses, payment terms, and compliance requirements. Integrating your ERP with your accounting system ensures seamless data syncing, cutting down on manual data entry. Real-time tracking of order status adds transparency and supports better decision-making.

This streamlined process also sets the stage for smoother handling of shipping notices, ensuring consistency from the moment an order is created to its delivery.

Automating Advanced Shipping Notice Processing

Advanced Shipping Notices (ASNs) are essential for keeping inventory accurate and ensuring smooth receiving operations. When processed through your ERP system, ASN automation eliminates manual errors and provides suppliers with clear guidelines for submitting data.

Walmart is a great example of this in action. In May 2024, they tightened their ASN standards and upgraded the ASN Dashboard in Retail Link, giving suppliers better tools to proactively identify and fix recurring submission errors.

Your ERP system can be configured to automatically validate ASN data against purchase orders, checking for discrepancies in item counts, packaging details, and carrier information before shipments even arrive.

Electronic Data Interchange (EDI) integration is a must for seamless ASN processing. Your ERP should be able to transmit electronic messages to trading partners, following each retailer’s specific formatting and data requirements. Regular testing of EDI mappings and monitoring acknowledgments can help catch and resolve errors quickly.

Automating ASN processing doesn’t just improve accuracy - it also enhances inventory planning. Accurate shipping notices allow your ERP system to update forecasts, allocate receiving resources, and prepare warehouse space, which minimizes supplier wait times and boosts overall supply chain efficiency.

Once you have reliable shipping data in place, the next step is to ensure real-time communication with suppliers.

Setting Up Automated Supplier Status Updates

Keeping suppliers in the loop with real-time updates is critical for avoiding delays and resolving issues quickly. ERP systems can automate these updates, ensuring suppliers always have the latest information on orders, payments, and performance metrics.

Microsoft Business Central provides a strong example of this. A logistics company struggling with inefficiencies in manual vendor communication implemented Business Central’s vendor portals. These portals gave suppliers real-time access to order statuses, shipping details, and invoices, streamlining collaboration. Automated alerts about shipment delays or issues allowed for immediate action, ultimately improving on-time delivery rates by 15%.

To set this up, configure your ERP system to provide suppliers with a secure portal where they can view purchase orders and update inventory levels. This self-service approach reduces the workload for your procurement team while giving suppliers the tools they need to perform effectively.

Automated alerts are another critical feature. Your ERP system should notify suppliers when orders are created, modified, or canceled, as well as provide updates on payment statuses, quality issues, or delivery schedule changes. Integration with email systems and APIs ensures these updates are sent through the supplier’s preferred communication channels, whether that’s email, EDI, or direct API connections.

By combining automated updates with efficient order and shipping processes, you create a robust communication system that drives better supplier performance across all procurement activities.

While automation handles routine updates, don’t overlook the importance of direct, personalized communication. Building strong, long-term relationships with suppliers requires a balance between automation and meaningful, strategic discussions.

sbb-itb-b077dd9

Using Real-Time Data to Track Supplier Performance

ERP systems take streamlined communication and automation to the next level by enabling real-time performance monitoring. With tools like automated procurement and live supplier updates, you can use ERP data to track supplier performance in real time. This capability provides the insights needed to act quickly and address potential issues before they escalate.

To make the most of this, set up monitoring tools within your ERP system. Use dashboards to display critical metrics, scorecards to measure performance against defined goals, and alerts to notify you of any red flags. These tools turn raw data into actionable steps that strengthen supplier relationships and improve supply chain efficiency.

Creating Supplier Performance Dashboards

Start by setting clear, SMART goals - like reducing delays, improving quality, or cutting procurement costs.

Your ERP system can pull data from various sources to give you a full picture of supplier performance. The key is to strike the right balance of performance indicators, such as on-time delivery rates, lead times, and shipment quality. Technically, this involves integrating your ERP with financial systems and business intelligence tools, while also customizing access levels. For instance, procurement teams might need detailed cost analyses, while suppliers could focus on order statuses and performance feedback.

Here’s an example: An aerospace component supplier implemented a structured performance management framework, including real-time quality monitoring and delivery tracking. The result? A 15% boost in on-time delivery rates and a 20% improvement in their product quality index.

Your ERP dashboard should serve as a one-stop shop for vendor information, consolidating contact details, contract terms, performance metrics, and full transaction histories into a single, easily accessible database.

Once your dashboard is ready, use scorecards to translate this data into actionable metrics.

Building Supplier Scorecards for KPI Tracking

Supplier scorecards take the data from dashboards and organize it into measurable performance ratings. These ratings track key areas like quality, delivery performance, cost competitiveness, responsiveness, and compliance with your benchmarks.

To calculate KPIs, use standardized formulas for metrics like on-time delivery, defect rates, order accuracy, and lead times. Configure your ERP system to automate data collection and reporting, ensuring regular updates. Schedule periodic performance reviews to evaluate whether suppliers meet your targets. Use these sessions to provide targeted feedback, highlighting successes and areas needing improvement.

Scorecards also make it easy to compare performance across vendors, helping you identify the top performers and those who need extra support. For underperformers, leverage scorecard data to develop improvement plans with clear steps and timelines. Document all related communications, reviews, and outcomes to build a transparent record.

To take it a step further, set performance thresholds that trigger automated alerts.

Setting Up Automated Performance Alerts

Real-time alerts can notify you of delayed shipments or quality issues, allowing you to adjust production schedules and plan for potential shortages. This proactive approach keeps small problems from snowballing into major disruptions.

Configure your ERP system to send alerts when performance drops below critical thresholds. For example, set notifications for when on-time delivery rates fall below acceptable levels. Quality alerts can flag excessive defect rates, while cost alerts can warn of unexpected price hikes or budget overruns.

The value of automated performance management is clear. Take Select Medical as an example: by digitizing its Procure-to-Pay process with Ivalua's Supplier Management software, they processed over 360,000 invoices and more than 263,000 purchase orders, managing over 10,000 contracts digitally. This led to multi-million dollar savings.

Make sure your alert system notifies the right stakeholders based on the type of issue. Delivery delays might go to the logistics team, while quality problems should alert both procurement and quality assurance. Set up escalation procedures so unresolved alerts automatically notify senior managers after a set time.

These automated systems let you stay on top of supplier performance without constant manual monitoring. This frees your team to focus on strategic tasks while ensuring performance issues are addressed promptly.

Building Supplier Improvement Programs Through ERP Tools

ERP tools have evolved beyond just tracking performance in real time - they now empower businesses to actively improve supplier operations. By leveraging insights from dashboards, scorecards, and alerts, companies can transition from merely identifying performance gaps to implementing structured improvement initiatives. This approach transforms supplier management from reactive problem-solving to proactive collaboration.

Creating Corrective Action Workflows

Corrective action workflows turn performance issues into opportunities for growth. A corrective action plan (CAP) is a structured method used to pinpoint, investigate, and correct deviations from established standards in manufacturing processes. ERP systems can simplify this process by automating key steps. For example, if a supplier's on-time delivery rate drops below 95%, the system can immediately trigger a CAP and assign it to the appropriate team for resolution.

The process begins with defining the issue - documenting specific deviations and their operational impact, such as missed quality metrics. ERP tools can then assist with root cause analysis, using historical data and communication records to uncover the underlying problem. Once the cause is identified, the system helps outline corrective measures, assign responsibilities, set deadlines, and allocate resources. Automated notifications and progress tracking ensure that resolutions are timely and efficient.

By streamlining these workflows, businesses can enhance data accuracy, improve operational efficiency, and foster consistent supplier performance improvements.

Setting Up Feedback Systems for Process Improvement

While corrective actions address immediate issues, feedback systems lay the groundwork for long-term collaboration and improvement. ERP systems can be configured to gather regular feedback from suppliers through automated surveys, embedded forms in supplier portals, or scheduled review sessions. These mechanisms are widely recognized as a best practice in ERP implementation.

Feedback systems help track progress and uncover inefficiencies. For instance, if a supplier suggests changes to product specifications or delivery processes, the ERP system can route these suggestions through approval workflows and provide dedicated spaces for collaboration.

To keep these systems effective, establish continuous feedback loops. Regular audits and updates to workflows ensure that processes remain efficient and aligned with supplier input. Insights from these systems can also guide updates to specifications and enhance collaboration tools.

For feedback systems to succeed, commitment is essential from both parties. Training suppliers to use these tools and ensuring that your team responds promptly creates a culture of collaboration. When both sides actively engage, shared insights lead to improvements that benefit everyone involved.

Conclusion: Achieving Better Supplier Performance with ERP Integration

Integrating ERP systems into supplier management shifts the focus from simply reacting to problems to building strategic partnerships. And the numbers speak for themselves - 95% of businesses report major improvements post-implementation, thanks to faster processes, stronger collaboration, and centralized data management. Additionally, 90% of distribution and manufacturing companies see substantial benefits in their supplier interactions.

One of the key advantages of ERP systems is their ability to consolidate data across departments into a unified platform. This centralization eliminates isolated data silos, providing real-time visibility - a feature valued by 80% of organizations. If a supplier misses a delivery deadline or quality issues arise, managers can quickly pinpoint the problem, trace its origins, and address it - all within the same system.

Automation further enhances efficiency by removing manual roadblocks. Tasks like purchase order processing, invoice management, and performance tracking become streamlined, allowing teams to focus on bigger-picture improvements. For instance, automation has been shown to increase on-time deliveries by 15% and reduce production delays by 20%.

The financial benefits are equally compelling. Over 80% of organizations report meeting their ROI goals with ERP implementations. Beyond ROI, businesses also see better inventory management and more effective performance tracking.

Strong supplier relationships thrive on communication and transparency. ERP systems make it possible for suppliers to access real-time updates on orders, delivery schedules, and performance metrics. This level of access fosters trust and transforms problem-solving into a collaborative effort. In the end, these partnerships are the backbone of consistent supplier performance.

Finally, maintaining a competitive edge requires ongoing improvement. By setting clear performance metrics, investing in employee training, and continuously monitoring results, businesses can ensure sustained growth and long-term success.

FAQs

How does ERP integration enhance communication with suppliers?

ERP integration improves supplier communication by streamlining essential workflows, offering real-time data access, and encouraging smoother collaboration. Tasks like managing orders and updating inventory become more efficient, cutting down on mistakes and delays.

With up-to-the-minute information at their fingertips, suppliers can stay informed about orders, stock availability, and delivery timelines. This level of transparency strengthens partnerships, ensures operations run more smoothly, and allows for quicker adjustments to shifts in demand or supply chain challenges.

How can I set up a centralized supplier database with an ERP system to improve supplier performance?

To create a centralized supplier database with an ERP system, start by setting clear objectives. Are you looking to streamline supplier collaboration, keep tabs on performance metrics, or improve order accuracy? Defining these goals will guide your process.

Next, determine the key supplier information you need to collect. This might include contact details, certifications, payment terms, and performance records. Knowing what data matters most ensures your database serves its purpose.

With your plan in place, choose an ERP system that supports supplier data management. Standardizing data entry formats is crucial to maintaining consistency and avoiding errors. Once your database is set up, integrate it with your ERP system to enable smooth communication and real-time updates.

Don’t forget the human element - train your team to use the system effectively. Regularly monitor the database to keep the information accurate and address any supplier performance gaps. A well-organized and up-to-date supplier database can make your supply chain more efficient and improve relationships with your suppliers.

How does automating procurement with ERP systems improve supplier performance?

Using ERP systems to automate procurement processes can greatly improve how suppliers perform. These systems make operations smoother, cut down on manual mistakes, and enhance communication between parties. By simplifying workflows, ERP systems can speed up procurement cycles, automate purchase orders, and provide real-time tracking of supplier performance metrics.

This means orders are more accurate, response times are faster, and collaboration with suppliers becomes more effective. Over time, these benefits help build stronger partnerships, open the door to negotiating better terms, and improve the overall efficiency of the supply chain.

.png?width=50&height=50&name=julie-miller-square%20(1).png)