Why PO & Inventory Visibility In the Supply Chain is Critical for Demand Forecasting

The most important goal for any supply chain is meeting demand. To that end, procurement and supply chain teams spend anywhere from 40% to 60% of their time calling and emailing suppliers, freight forwarders, and third-party partners to get updates on their purchase order statuses. They are constantly asking, “Where’s my stuff?”

The answer to that question plays a crucial role in demand forecasting, which helps determine whether there is enough current stock and incoming product to cover demand. Accurate forecasting relies on inventory visibility and purchase order status visibility. Knowing at a glance where goods are in any phase of the PO lifecycle — in production, post-production, in transit, at a port, or delivered — can alert teams to potential shortages early, allowing them to take proactive steps to avoid shortages and backorders.

This article explores why demand forecasting is crucial to supply chain success and why purchase order and inventory visibility are essential for accurate demand forecasts. Though there are numerous challenges to creating purchase order visibility, the right tools and technology can help develop optimized workflows for meeting demand.

Why Demand Forecasting is Crucial to Supply Chain Success

When it comes to demand forecasting, the most reliable metric would be real-time purchases — every unit sold would signal the need to place an order for a replacement, and goods would flow in and out seamlessly. Of course, the reality of supply chain demand forecasting is not nearly so simple. It involves tracking purchase orders from numerous suppliers and monitoring on-hand supply to meet known and predicted demand.

Building a demand forecast starts with identifying three factors:

- Stock cover: the amount of time that the supply of goods in a company’s inventory will last given the current rate of sales.

- Lead time: the amount of time between placing an order and receiving the stock from a supplier.

- Safety stock: the amount of stock always needed on hand as a backup.

When implemented correctly, demand forecasts provide valuable insight for procurement teams and identify potential problems early and address them proactively. By identifying delays in supplier production or transportation in advance, procurement teams can expedite additional orders from alternative suppliers to avoid going out of stock. Over time forecasts can also aid in supplier evaluations as they track on-time, in-full deliveries, and other services’ KPIs, creating more efficient supply chains and better supplier relationships.

Why PO & Inventory Visibility is Essential for Demand Forecasting

Demand forecasting requires a high level of inventory visibility in the supply chain. Inventory visibility and purchase order visibility provides a consolidated overview of current product quantities, incoming orders, when items will arrive, and how SKUs roll up to finished goods. This information is vital for avoiding stockouts and maintaining a healthy, efficient supply chain.

The basic definition of inventory visibility is knowing what product is on hand and its location at any moment, but the reality is far from simple. Modern supply chains often operate globally between multiple suppliers, warehouses, transportation vessels, and distributors. Inventory levels at each stage need to be counted accurately to balance supply with demand and avoid stockouts. Collecting reliable, up-to-date information every step of the way is essential for comprehensive demand forecasting, but it also presents several challenges.

Challenges of Inventory & Purchase Order Visibility

Inventory and order visibility provide valuable and critical information for supply chain and procurement teams, but they are highly dependent on accurate data. This data may include information from many documents and providers and may come in disparate formats and mediums. Consider a fundamental process for ordering inventory to restock and prepare for projected customer orders or production schedules:

- Inventory trigger: procurement team receives notification that an item needs restocking, based on current inventory levels or a change in projected demand (new customers, a shift in consumer habits, etc.)

- Purchase order: an order for the item is issued to the supplier. This order might be placed online, via email, or by phone.

- Confirmation and shipping: supplier confirms the order, provides a packing list, and notifies when an order has shipped. Notifications may be sent to online customer portals or in an email.

- Transportation: providers confirm a shipment is in transit and provides ETAs and status updates throughout the process. This may involve numerous parties like freight forwarders, customs brokers, trucking companies, and small parcel providers, with updates across multiple platforms.

- Receiving and inventory management: shipment is received, counted, and added to on-hand inventory systems.

Traditional manual inventory and purchase order visibility systems are labor-intensive and require the procurement team to monitor PO statuses constantly throughout the transaction. Additionally, these processes often rely on spreadsheets or inventory software that require manual data input for updates. Therefore, a procurement team that manages hundreds to thousands of POs in a month has an enormous responsibility of monitoring, tracking, and inputting data to get accurate inventory visibility. Errors or missing data can quickly lead to stockouts and leave teams in a reactive position — trying to address issues far too late.

These challenges exist even in best-case scenarios for the supply chain but are exacerbated in times of distress. The COVID-19 pandemic impacted many businesses, and the ripples it created in the supply chain continue to be extremely damaging. Stalled production, extended transit times, and capacity shortages have created major hurdles for accurately managing inventory and have put tremendous stress on procurement teams. The manual processes for tracking POs and updating inventory visibility and demand forecasting systems are more challenging than ever.

Benefits of PO & Inventory Visibility in the Supply Chain

Accurate inventory visibility and purchase order visibility provide a comprehensive picture of incoming purchase orders by date of expected delivery. With an automated control tower solution such as the Leverage Platform, this inbound PO data can overlay on top inventory and demand targets to identify where gaps exist. It creates a heat map of risk levels for any individual item at any location. If the data reflects a high risk of not meeting demand, the platform will automatically trigger a recommendation to create a purchase order to fill the potential gap. A gap is determined as follows:

Gap = Demand Target - (Inventory on a certain date + POs expected to be there)

Additional benefits of demand forecasting with purchase order visibility and inventory visibility in place include:

- Meet customer demand: when customers are satisfied, they are more likely tol expand the business relationship and become brand ambassadors, too. After all, good news travels fast.

- Generate revenue: demonstrated ability to meet demand consistently opens new doors of opportunity to grow business.

- Control inventory costs: maintaining inventory in the right amounts means meeting demand while avoiding a surplus of stock on-hand and minimizing inventory costs.

- Attaching inventory visibility and PO visibility to account for goods in transit: identifies risks sooner and drives proactive mitigation efforts.

There is no doubt that inventory and purchase order visibility plays a vital role in demand forecasting, but how can it be done accurately and efficiently without draining a procurement team’s time and resources?

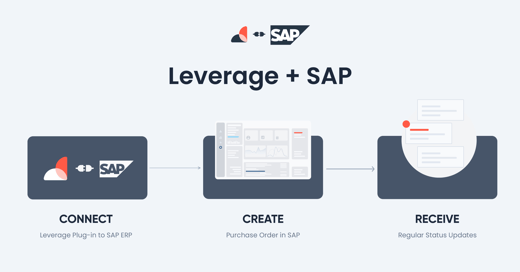

Partnering with Leverage for Better PO and Inventory Visibility

Leverage delivers end-to-end PO lifecycle visibility powered by artificial intelligence. More than simply tracking POs, Leverage’s control tower platform automates the status update process by connecting directly with suppliers and transportation providers across a variety of channels. ERP, EDI, email, WhatsApp, Wechat — Leverage meets suppliers where they are in order to maintain easy, seamless communication. PO updates track into the Leverage platform and work in tandem with current inventory counts, ensuring that every item is replenished in time, and alerting procurement teams of potential gaps.

Imagine a world in which inventory visibility in the supply chain was not only possible but automated and efficient. A world in which procurement teams no longer spent 40-60% of their time chasing suppliers for updates and asking, “Where’s my stuff?” and inventory delays could be addressed proactively. Contact the experts at Leverage today to learn more about their simple integration for easy, automated purchase order visibility.

.png?width=520&height=294&name=Logo%20+%20Name%20Dark%20(1).png)