AI-Powered Delivery Accuracy: Supplier Performance Impact

.png?width=50&height=50&name=elizabeth-anderson-square%20(1).png)

AI is transforming delivery accuracy by improving supplier performance and supply chain reliability. Missed shipments and delays can halt production, raise costs, and damage customer trust. Traditional manual methods - like spreadsheets and emails - are slow and error-prone, making it hard to track supplier performance or predict risks.

AI tools solve these issues by automating data collection, providing real-time updates, and predicting potential delays. With AI platforms like Leverage AI, companies gain immediate insights into delivery schedules, supplier quality, and performance metrics. This shift reduces late deliveries by up to 30%, cuts logistics costs by 10–20%, and improves service levels by 15–30%.

Key benefits of AI-powered supplier management include:

- Real-time tracking of shipments to prevent delays.

- Automated supplier scoring for consistent evaluations.

- Predictive risk detection to address issues before they escalate.

- ERP integration for seamless data flow and accuracy.

Switching to AI systems enables companies to optimize operations, reduce manual workloads, and maintain reliable delivery schedules, giving them a competitive edge in today’s market.

How Agentic AI Is Secretly Revolutionizing Supply Chains (Real-World Examples!)

1. Manual Supplier Management Methods

For years, manufacturers and distributors across the U.S. have relied on manual processes to manage supplier relationships and track deliveries. These methods - using spreadsheets, email chains, phone calls, and occasional reviews - often lead to inefficiencies and errors. The primary issue? These systems are reactive and lack real-time data, making it difficult to ensure delivery accuracy and efficient operations.

Delivery Time Accuracy

Managing delivery schedules manually is a logistical headache. Procurement teams frequently waste hours chasing updates through phone calls, emails, or supplier portals. For instance, a shipment expected on Tuesday might not be flagged as late until days afterward, by which time production schedules are already disrupted. This often results in costly expedited shipping to meet deadlines.

Data highlights the problem: McKinsey research shows that companies using manual supplier management methods experience 20–30% more late deliveries than those with automated, data-driven systems. Similarly, a 2024 Supply Chain Dive report revealed that 57% of manufacturers still rely on spreadsheets for tracking supplier performance. These spreadsheets are often updated inconsistently, and when key personnel are unavailable, critical knowledge about suppliers can easily slip through the cracks.

Supplier Performance Tracking

Manual tracking systems gather scattered and inconsistent data. For example, purchase order details might sit in an ERP system, while email confirmations, quality issues, and delivery dates are stored separately. This fragmented approach delays corrective actions, allowing supplier issues to escalate and affect multiple orders.

A 2022 Gartner survey found that businesses using manual methods for supplier performance management spend 30–50% more time on administrative tasks compared to those with automated systems. This extra workload leaves little time for higher-value tasks like supplier development or risk management. Additionally, inconsistencies in metrics - such as varying ways to calculate on-time delivery rates - make it hard to evaluate suppliers fairly. Many companies still rely on Excel-based scorecards, updated sporadically, which can delay access to critical performance data when leadership needs it.

Predictive Risk Detection

Manual processes also lack the ability to predict risks. Teams can only react to problems once they arise. For instance, a supplier struggling with financial issues or capacity constraints might continue receiving orders until a major failure occurs - such as a missed shipment or defective batch. Without real-time data, these warning signs often go unnoticed until they cause significant disruptions.

A 2023 Deloitte study found that 68% of procurement leaders see manual processes as a major barrier to supply chain visibility and responsiveness. This reactive approach often forces companies to stockpile excess inventory, tying up capital and warehouse space while still leaving them vulnerable to unforeseen disruptions.

Integration with ERP Systems

In manual setups, supplier management and ERP systems rarely work seamlessly together. While purchase orders may originate in the ERP, tracking their progress typically requires external follow-ups. Buyers often log updates from supplier emails or phone calls manually, entering shipment confirmations and delivery dates one at a time. This fragmented data entry increases the likelihood of errors and delays, creating confusion across departments. Production planning might rely on outdated ERP data, customer service struggles to provide accurate delivery estimates, and finance faces difficulties forecasting cash flow due to unreliable delivery schedules.

Scaling manual processes is another challenge. Managing 50 suppliers through spreadsheets and emails may work, but when that number grows to 500, the complexity becomes unmanageable. Companies are then forced to either expand their procurement teams significantly or accept reduced visibility and control over supplier performance.

2. AI-Based Supplier Management Solutions (e.g., Leverage AI)

AI-driven supplier management platforms are reshaping how U.S. manufacturers and distributors handle deliveries and interact with suppliers. These systems pull in real-time data from ERPs, logistics, quality records, and IoT sensors to track metrics like on-time deliveries, quality, and costs on a continuous basis. Gone are the days of delayed, manual reporting - now, procurement teams can rely on live dashboards that update automatically.

This shift from periodic updates to continuous monitoring has fundamentally changed supplier relationship management. Instead of reacting to issues after production is disrupted, AI platforms use predictive insights and automated workflows to address potential problems upfront. This constant data stream enables a more proactive approach to supplier management.

Delivery Time Accuracy

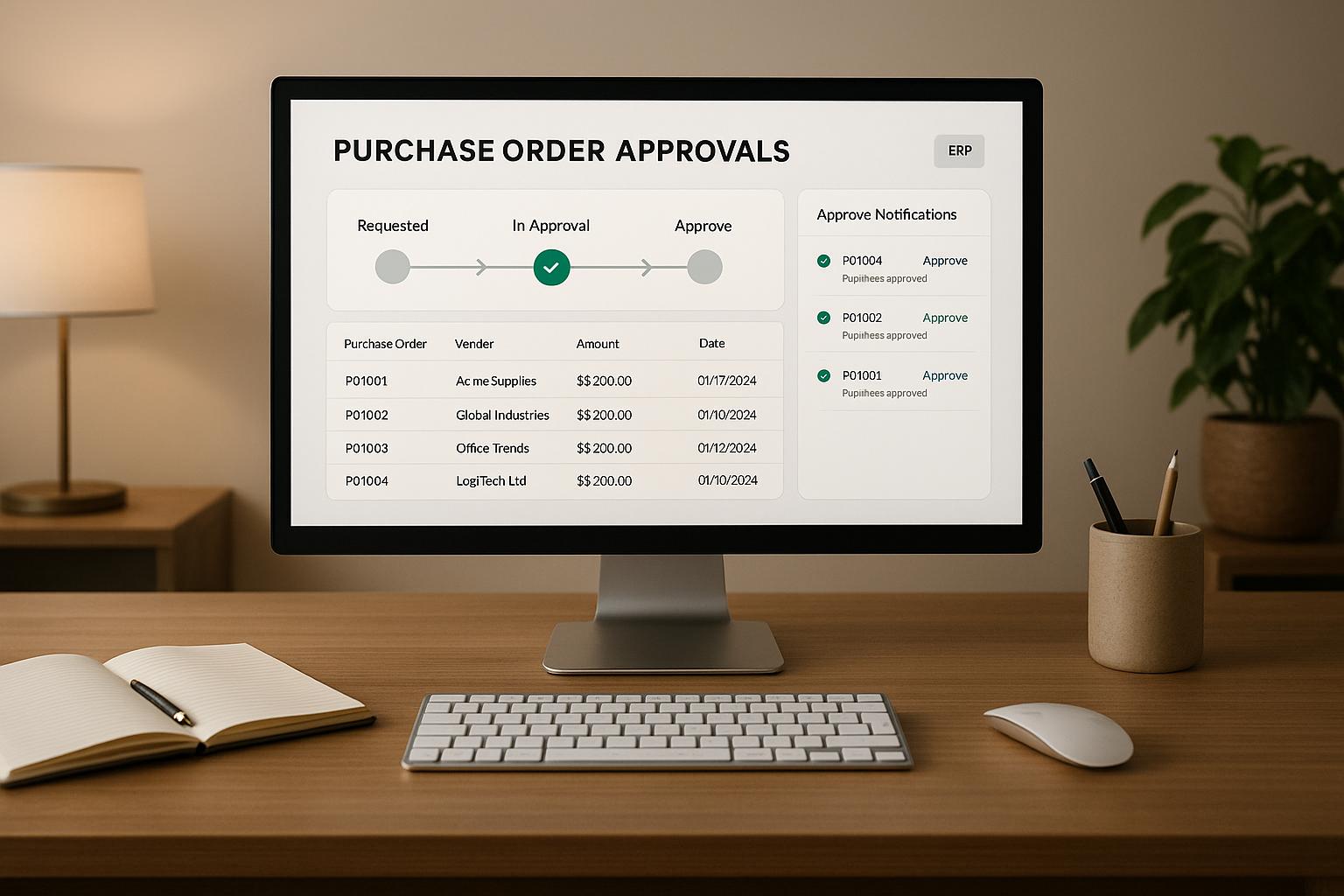

AI platforms significantly boost delivery time accuracy by offering real-time visibility into shipment statuses and alerting teams to possible delays. For example, Leverage AI automates supplier follow-ups, eliminating the need for buyers to send emails or make phone calls. The system handles tasks like acknowledgment requests, updates on lead times, and shipment notifications, feeding this information directly into the ERP system. This automation not only prevents production delays but also saves buyers an estimated 50% of their time each week, according to Leverage AI. This allows procurement teams to focus on more strategic supplier development tasks.

With this real-time insight, companies can react quickly to potential delays. If a critical shipment is at risk, they can expedite orders, adjust production schedules, or communicate with customers - all based on accurate, up-to-date data instead of outdated estimates.

Research shows that AI tools can reduce inventory levels by 15–20% and cut logistics costs by 10–20%. These savings are largely due to improved supplier performance and more reliable delivery schedules.

Supplier Performance Tracking

AI platforms take supplier performance tracking to the next level by providing real-time, consistent evaluations. Unlike manual tracking, which often involves compiling data at the end of a quarter, AI systems score suppliers continuously across multiple metrics - such as on-time delivery, lead-time variability, quality issues, responsiveness, and sustainability. These scores are updated automatically as new data flows in from ERP systems and quality checks.

When a supplier’s performance starts to dip below acceptable thresholds, the system triggers alerts and initiates corrective actions. This early intervention prevents small issues from snowballing into major disruptions.

AI also ensures standardized evaluations. Instead of relying on inconsistent, subjective assessments that vary by region or individual, these platforms apply uniform scoring models across all suppliers. Many systems even allow suppliers to access their own performance dashboards, fostering transparency and encouraging collaborative problem-solving.

According to GEP, these AI tools can cut manual reconciliation time from days to just minutes. This enhanced visibility means procurement teams can quickly address late shipments or cost variances before they escalate.

Predictive Risk Detection

One of the standout benefits of AI-based supplier management is its ability to predict risks before they happen. By analyzing historical performance, current trends, and external factors, AI systems can forecast potential delays, compliance issues, or cost increases well in advance. For instance, if a supplier’s on-time delivery rate is steadily declining while quality rejections are increasing, the system can flag them as high-risk before a major disruption occurs. This allows companies to reassign critical orders or adjust safety stock levels proactively.

A KPMG survey found that 67% of organizations plan to increase their investment in AI for supply management, with supplier performance and risk management being top priorities. This trend underscores the competitive edge that predictive analytics provide, helping companies stay ahead of potential disruptions.

Integrating these predictive insights with ERP systems completes the digital supply chain loop, ensuring that data flows seamlessly across platforms.

Integration with ERP Systems

Seamless integration with ERP systems is a cornerstone of effective AI-powered supplier management. Modern AI platforms come with pre-built connectors for major ERPs like SAP, Oracle, and Microsoft Dynamics. These connectors enable automatic syncing of purchase orders, goods receipts, invoices, quality records, and supplier data in both directions. This ensures the ERP remains the central source of truth, while the AI layer adds intelligence and automation.

With accurate delivery dates, production planning becomes more reliable, customer service can provide precise updates, and finance teams can forecast cash flow based on real-time payment schedules.

Eric Swope, COO of Buckle Down, highlighted the impact of this integration:

"Leverage is a total game-changer for us. I can't believe we managed our supply chain without this level of visibility before."

This integration also supports workflows that span both systems. For instance, when a supplier acknowledges a purchase order through the AI platform, the ERP is automatically updated, flagging any discrepancies with production schedules for review. Automated workflows like these ensure that mismatches between promised and actual delivery dates are identified and resolved quickly.

Additionally, the cloud-based nature of modern AI platforms makes scaling easier. As businesses grow, these systems can handle more complex supplier networks without requiring additional manual oversight, maintaining efficiency across the board.

sbb-itb-b077dd9

Strengths and Weaknesses

After closely examining both manual and AI-powered approaches, it becomes clear that each has its own set of advantages and drawbacks. U.S. manufacturers and distributors must carefully evaluate these trade-offs to choose the best fit for their supply chain strategy.

Manual supplier management methods are appealing for their low upfront costs and the direct control they offer over supplier relationships. For smaller operations with a limited number of trusted suppliers, tools like spreadsheets and simple phone calls might get the job done. But as the supplier network grows or customer expectations for timely deliveries intensify, these methods can quickly become inefficient. Tracking updates manually becomes overwhelming, and critical early warning signs may be missed during routine reviews.

On the other hand, AI-driven solutions, such as Leverage AI, require a higher initial investment and organizational adjustments but deliver lower ongoing costs per supplier. According to a McKinsey study, incorporating advanced analytics and AI into supply chain planning can improve service levels by up to 65% and cut supply chain costs by as much as 20%. These platforms automate repetitive tasks, like follow-ups, freeing up buyers to focus on strategic decisions.

Here’s a quick comparison of the two approaches:

| Feature/Aspect | Manual Methods | AI-Based Solutions (e.g., Leverage AI) |

|---|---|---|

| Delivery Time Accuracy | Relies on reactive updates, with delays often discovered after they happen. Buyers spend time chasing updates via calls or emails, which can lead to errors. | Tracks orders in real-time and sends automated alerts for potential delays. Provides continuous updates on lead times and shipments, allowing proactive responses. |

| Supplier Performance Tracking | Periodic, labor-intensive manual reviews (e.g., quarterly or annually), which may leave gaps in monitoring. | Offers automated, ongoing tracking with standardized scoring for all suppliers. Real-time updates on key metrics like delivery timeliness, quality, and responsiveness. |

| Predictive Risk Detection | Limited to analyzing past data, identifying risks only after they’ve occurred. | Uses historical trends, current data, and external factors to forecast risks in real time. AI systems detect early warning signs and suggest corrective actions. |

| ERP Integration | Requires manual data entry, often leading to errors and delays across teams. | Seamlessly integrates with major ERP systems, syncing data in real time while preserving system integrity. |

| Scalability & Workload | As the number of suppliers grows, so does the workload, often necessitating additional staff. | Automation allows small teams to manage larger supplier networks efficiently, focusing on high-risk or underperforming vendors. |

| Objectivity & Consistency | Evaluations can be subjective, influenced by individual judgment or historical relationships, making comparisons difficult. | Employs standardized algorithms and KPIs for consistent, unbiased evaluations across all suppliers. |

AI systems stand out for their ability to consistently apply objective criteria, minimizing the influence of personal biases.

However, AI-based solutions are not without challenges. Issues like poor data quality or incomplete ERP records can lead to errors on a larger scale. To mitigate these risks, starting with a pilot program focused on critical suppliers or high-impact categories can help demonstrate the system’s value before a full rollout. Pairing AI insights with strong governance protocols ensures that performance declines can be addressed quickly and effectively.

For U.S. manufacturers and distributors dealing with increasingly complex supplier networks, transitioning from manual methods to AI-driven management can significantly enhance customer satisfaction while streamlining operations.

Conclusion

Switching from manual supplier management to AI-powered solutions isn’t just about upgrading technology - it’s about transforming how U.S. manufacturers and distributors achieve consistent delivery accuracy and strengthen supply chain resilience. With AI, on-time performance can jump by 15–30 percentage points, even exceeding 95% when risks are addressed proactively. Variability in lead times drops by 20–40%, making production schedules more predictable and improving customer satisfaction.

AI tools do more than improve delivery accuracy - they simplify daily workflows. By automating tasks like tracking, follow-ups, and supplier scoring, companies can reduce manual workloads by 30–50%. This efficiency allows procurement teams to handle larger supplier networks without adding staff. Steve Andrews, Director of Systems Control, shared his experience with Leverage AI:

"Leverage saves each of our buyers at least 50% of their time every week, and we were able to reduce our planned headcount."

These time savings have a ripple effect, enabling procurement teams to focus on strategic decisions rather than chasing updates. Buyers can reallocate orders from at-risk suppliers, strengthen ties with reliable partners, and address performance issues before they disrupt operations.

In today’s unpredictable supply environment, AI’s ability to reduce risks is essential. Predictive analytics spot warning signs early - like rising defect rates or unusual shipment patterns - and trigger alerts or corrective actions before small problems escalate. Some mid-sized manufacturers have seen supplier-related production disruptions drop by 40% using this proactive approach.

For businesses exploring AI solutions, the priority is finding a platform that integrates smoothly with existing ERP systems while offering real-time visibility and automation. Leverage AI checks these boxes by automating supplier follow-ups, monitoring purchase orders in real time, and providing actionable performance data. Its unified dashboards centralize information, empowering procurement teams to make quick, informed decisions.

With these advancements, U.S. manufacturers can confidently adopt a proactive supply chain model. Starting with high-impact suppliers or critical categories, organizations can pilot AI solutions, measure improvements in delivery accuracy and efficiency, and then expand adoption across their supplier base. Companies making this shift now will secure a competitive edge with better delivery performance, reduced costs, and stronger supplier partnerships - advantages that will only grow as supply chains become more intricate.

FAQs

How does AI help improve supplier performance and ensure more accurate delivery times?

AI helps boost delivery accuracy by simplifying how businesses track and manage supplier performance. Through automation, tasks like supplier follow-ups become more efficient, while real-time data provides instant visibility into operations. This means potential delays can be spotted and addressed much faster.

By improving supplier communication and delivering detailed performance insights, AI empowers manufacturers and distributors to make informed decisions. The result? Smoother operations and a stronger ability to meet delivery deadlines.

How do AI-powered solutions integrated with ERP systems improve supplier management?

AI-driven tools simplify supplier management by automating repetitive tasks, such as follow-ups, and enhancing communication with suppliers. These solutions offer real-time insights, making it easier to spot and resolve potential delays, which helps keep operations running smoothly.

When integrated with ERP systems, AI boosts supply chain visibility, monitors supplier performance, and streamlines tasks like managing purchase orders. This results in more precise delivery timelines and smarter decision-making for manufacturers and distributors.

How does AI help predict risks in the supply chain to avoid disruptions and improve reliability?

AI strengthens supply chain reliability by leveraging predictive analytics to spot potential risks before they turn into major disruptions. By processing real-time data from suppliers, logistics channels, and market trends, AI can uncover patterns and predict delays, shortages, or other challenges.

This forward-thinking approach enables businesses to act swiftly, adapt their strategies, and keep operations running seamlessly. Tools like automated supplier follow-ups and performance monitoring improve collaboration and transparency, ensuring more accurate deliveries and happier customers.

.png?width=50&height=50&name=elizabeth-anderson-square%20(1).png)