How Multi-Tier Supplier Portals Scale with Business Growth

%202%20(1).png?width=50&height=50&name=20250501_1415_Professional%20LinkedIn%20Update_remix_01jt6gxkjmekavnvzsewk61z9w%20(1)%202%20(1).png)

TL;DR: Multi-tier supplier portals integrate Tier 1, Tier 2, and Tier 3 suppliers into a single platform, improving supply chain visibility, risk management, and scalability. By leveraging modern architecture, automation, and AI, businesses can handle growing supplier networks, reduce disruptions, and optimize operations.

Your supply chain is only as strong as its weakest link. A multi-tier supplier portal centralizes your entire supplier network, allowing you to identify risks, streamline processes, and scale efficiently. Key features include AI-powered insights, modular design for scalability, and automation for onboarding and communication. These tools ensure your portal can grow alongside your business while maintaining performance and compliance.

The New Visibility: Unlocking Multi-Tier Transparency And Traceability

sbb-itb-b077dd9

Designing Supplier Portals That Scale

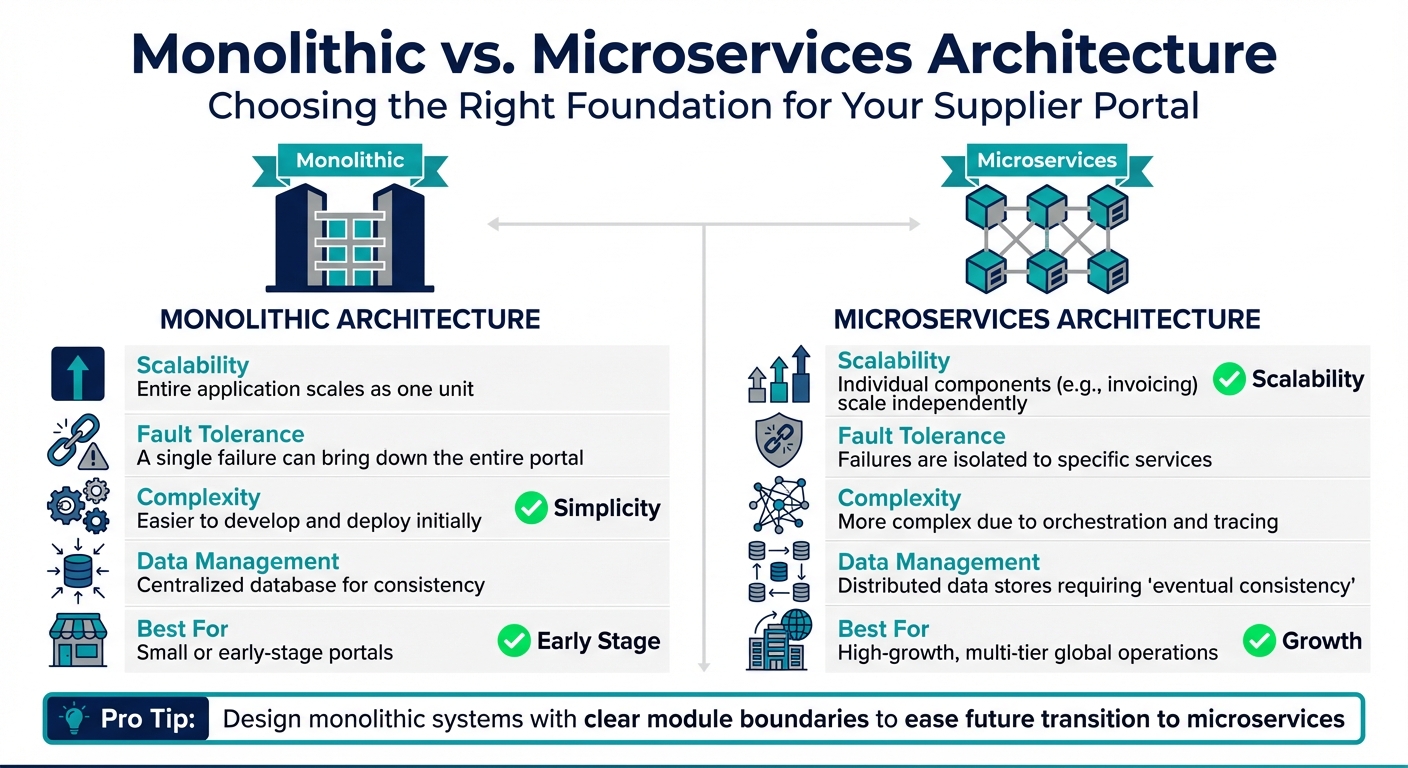

Monolithic vs Microservices Architecture for Supplier Portals

When building a supplier portal, it’s crucial to think ahead. The design choices you make today will determine whether you can seamlessly manage 1,000 suppliers tomorrow - or struggle as your network grows. A solid foundation keeps operations efficient and avoids expensive overhauls later. Below, we’ll explore the core design elements that help your portal scale alongside your supplier network.

Core Architecture Principles

The backbone of a scalable portal lies in horizontal scalability. Instead of upgrading existing servers, you simply add more instances of the same resource. This approach ensures your system can handle sudden spikes in supplier activity without hitting hardware limits.

A stateless architecture is another critical element. By storing session data externally rather than tying it to specific servers, any server can handle any request. This eliminates bottlenecks and ensures smooth performance, even as user demand grows.

Decoupling and modularity allow you to break your portal into independent components connected by APIs. For example, your supplier onboarding module can scale independently of your invoicing system. This means a surge in new supplier sign-ups won’t disrupt payment processing, and issues in one area won’t bring down the entire portal.

To maintain responsiveness under heavy workloads, asynchronous communication is key. For instance, when a supplier uploads a large batch of documents, message queues handle the processing in the background, allowing users to continue working without delays. This ensures consistent performance as data volumes grow.

These architectural principles ensure your portal is equipped to handle increased data and user demands.

Planning for Data and User Growth

As your supplier base expands, your database can quickly become a bottleneck. Sharding - dividing your database into horizontal partitions based on criteria like Supplier ID - keeps performance steady as records increase. Implementing sharding early avoids complex migrations down the line.

The unit scaling approach bundles related resources like web servers, queues, and databases into groups that scale as a single unit. When additional capacity is needed, you deploy a new unit instead of adding resources piecemeal. This keeps performance balanced across all components and simplifies planning.

Vertical partitioning separates frequently accessed data (e.g., supplier contact details) from rarely used information (like historical invoices). This ensures common queries run faster. Functional partitioning takes it a step further by dividing data based on business functions, so systems like onboarding, invoicing, and product data can scale independently.

These strategies ensure your portal remains fast and efficient, regardless of how much your supplier network grows.

Microservices vs. Monolithic Architectures

When deciding between a monolithic or microservices architecture, consider your current size and growth plans. A monolithic architecture combines all functions into one deployment, while microservices divide your portal into independent services that can evolve separately. Here’s a comparison:

| Feature | Monolithic Architecture | Microservices Architecture |

|---|---|---|

| Scalability | Entire application scales as one unit | Individual components (e.g., invoicing) scale independently |

| Fault Tolerance | A single failure can bring down the entire portal | Failures are isolated to specific services |

| Complexity | Easier to develop and deploy initially | More complex due to orchestration and tracing |

| Data Management | Centralized database for consistency | Distributed data stores requiring "eventual consistency" |

| Recommendation | Best for small or early-stage portals | Ideal for high-growth, multi-tier global operations |

For small businesses or those just starting out, a monolithic architecture can work well. However, it’s wise to design it with clear module boundaries, making it easier to transition to microservices later. For larger, established operations managing thousands of suppliers, microservices provide the flexibility to scale specific functions as needed without over-provisioning resources for the entire system.

Using Automation to Improve Efficiency

As your supplier network grows, relying on manual processes becomes impractical. Did you know 60–70% of procurement time is spent on manual tasks like tracking purchase orders and following up on invoices? Automation completely transforms this dynamic, enabling you to handle hundreds or even thousands of suppliers without needing to expand your team proportionally. These strategies align with core design principles, ensuring smooth and scalable growth.

Automating Supplier Onboarding and Communication

Onboarding new suppliers shouldn't take weeks of endless emails. Automated tools can simplify the process by categorizing suppliers based on factors like importance, transaction volume, and technical readiness. This streamlines both account setup and ongoing communication. The result is a centralized communication hub - a "single source of truth" - that captures all interactions in a system built on trust.

Supplier self-service tools and AI-integrated ERP systems further reduce administrative workload. Suppliers can propose digital changes to purchase orders, upload compliance documents, and manage their own tasks directly within the system. This level of efficiency becomes essential as you expand across multiple supplier tiers.

Real-Time Insights and Tracking

Once onboarding is optimized, real-time insights take supplier management to the next level. Instead of reacting to issues, you can proactively address them. Currently, only 25% of organizations have visibility into more than half of their Tier 2 suppliers. This lack of visibility leaves businesses vulnerable to disruptions that could ripple through their supply chains. Real-time tracking fixes this by identifying delays and bottlenecks before they escalate.

Leverage AI offers real-time supply chain visibility that integrates seamlessly with ERP systems. It automatically tracks purchase orders and monitors supplier performance. This kind of automation delivers tangible results, such as reducing Days Sales Outstanding (DSO) by 7–15 days and achieving first-time invoice acceptance rates above 99%. As Daniel Asraf from Monto explains:

"The question is no longer whether to automate, but how quickly you can implement AI solutions before the competition leaves you behind."

Continuous Improvement Through CI/CD

Supplier portals require constant updates to stay functional and secure, especially as your business evolves. Continuous Integration/Continuous Deployment (CI/CD) pipelines ensure that updates, security patches, and new features are implemented without disrupting daily operations.

This approach also enables ongoing monitoring of key performance indicators (KPIs), allowing real-time adjustments to supplier strategies as market conditions change. Automated workflows can trigger reminders or alerts based on service-level agreements (SLAs) - for instance, flagging when a supplier hasn’t responded within five business days. These updates maintain data accuracy and prevent system failures in complex, multi-tier supply chains. By aligning with scalability goals, CI/CD ensures your supplier portal evolves alongside your growing network.

Managing Governance and Compliance at Scale

When governance is fragmented, it opens the door to costly regulatory violations and operational missteps. Just as scalable architecture supports growth, scalable governance is crucial for managing expanding supplier networks effectively.

Setting Up Governance Frameworks

Building strong governance starts with a centralized committee that unites procurement, legal, compliance, finance, and IT teams. This group defines a clear matrix of roles and responsibilities, specifying who ensures data quality, who approves supplier access, and who oversees risk across the network. Without clear accountability, governance efforts often fall apart.

Adopting standardized frameworks like ISO 31000 for risk taxonomy - covering areas such as financial, liquidity, and solvency risks - helps streamline risk assessments across regions. For cybersecurity, NIST SP 800-161 offers a layered approach to identifying and addressing supply chain threats. These frameworks enable consistent and repeatable risk evaluations as new supplier tiers are added.

Maintaining data integrity is another cornerstone of governance. A "golden record", or single authoritative source for supplier information, is critical. Supplier Master Data Management (SMDM) ensures uniformity from the moment data is entered, reducing fragmentation. Your supplier portal should require standardized formats for legal names, tax IDs, and parent-subsidiary relationships. Automated validations can catch errors before they reach your ERP system, preserving data quality and improving decision-making. As Richard Teuchler of Kodiak Hub notes:

"If your supplier data is fragmented, every downstream process (from RFx to audits) inherits that noise."

Access control is equally important. The AWS Supply Chain Lens recommends implementing granular access controls using IAM and SSO solutions. This ensures that third parties have access only to what their roles require - no more, no less. This principle of least privilege is essential, especially since over 60% of organizations reported third-party breaches in the past year.

These measures create a foundation for balancing operational flexibility with strict compliance, as explored in the next section.

Balancing Customization and Standardization

Customizing your portal for every supplier may seem appealing, but it can quickly become unmanageable. A better approach is to use tiered assessment models that align the depth of governance with the level of supplier risk. For example, low-risk vendors might complete simple self-certification forms, while high-risk or strategic partners undergo more rigorous evaluations and third-party verifications. This approach, combined with branching logic in questionnaires, avoids the inefficiency of a one-size-fits-all model.

| Category | Governance | Customization |

|---|---|---|

| Strategic | High-touch, joint performance dashboards | High (Co-innovation focus) |

| Preferred | Standardized performance monitoring | Medium (SLA tracking) |

| Transactional | Automated, self-service onboarding | Low (Standardized forms) |

| Risk-Critical | Continuous monitoring, strict audit trails | High (Specific compliance needs) |

Delegated administration allows partner administrators to manage their own users within a governed framework. OpenText describes this shift:

"The 2026 supplier portal must close that gap with delegated administration that empowers partner administrators to manage their own users within a governed framework..."

Lastly, no-code workflow builders provide flexibility without compromising standardization. These tools let business users configure processes like self-assessments or document uploads without needing IT intervention or altering the core system architecture. This approach ensures standardization where it's most critical while offering adaptability for specific business needs as your supply chain grows.

Monitoring and Improving Performance

Operating without real-time performance data can make scaling a risky endeavor. This strategy for monitoring performance complements earlier discussions on scalable architecture and automation. By keeping a close eye on performance, you can ensure your system handles peak loads, stays reliable during critical moments, and provides the insights needed to allocate resources effectively as your network grows.

Defining Key Performance Metrics

Before scaling, it's essential to set performance baselines and establish Service Level Agreements (SLAs) for all systems, including third-party integrations. These benchmarks help you spot deviations early. Pay attention to key metrics such as system health - tracked through response times, error rates, and data loss - and overall cost efficiency.

The AWS Supply Chain Lens highlights the importance of this approach:

"Performance monitoring and testing are critical components of supply chain management as they make sure systems can handle varying loads, maintain reliability during peak operations, and provide visibility into system behavior across complex, interconnected supply chain networks."

Adjust monitoring frequency based on supplier importance. For mission-critical suppliers, reviews should occur monthly or quarterly, while low-risk vendors might only need annual reviews. Automated alerts are a must - set them up to notify you of SLA breaches. For instance, you could trigger an alert if a supplier fails to respond to a purchase order within five business days.

Once you have these metrics in place, advanced observability tools can help uncover the root causes of performance issues.

Implementing Observability Tools

While basic monitoring tells you something is wrong, observability helps you understand why. Distributed tracing is a key tool here, allowing you to identify delays in multi-tier workflows. Using correlation IDs across all application components enables you to trace a single transaction through multiple services, making it easier to diagnose failures in distributed systems.

Keep an eye on telemetry data for external dependencies like third-party APIs, DNS services, and databases - these can silently become bottlenecks that hurt overall reliability. Tools like Azure Monitor or AWS CloudWatch are excellent for centralizing telemetry data, making it easier to cross-query and analyze information from different sources. Embedding custom trace events can provide additional insights into throughput and latency. To maintain accuracy, make sure production performance data is kept separate from non-production environments; this avoids skewed benchmarks caused by testing activities.

The insights gained from observability tools feed directly into scalability assessments and help refine cost management strategies.

Scalability Assessments and Cost Optimization

Regular scalability assessments are crucial for confirming your system's ability to handle peak loads while staying cost-efficient. Incorporate performance testing into your release cycle to catch bottlenecks before they disrupt live operations. Use monitoring data to calculate supplier volume capacity, aggregate information at different levels, and forecast potential shortages to plan sourcing more effectively.

Tie supply chain metrics to business goals to identify trade-offs and prioritize initiatives that deliver measurable cost savings. When evaluating portal platforms, consider how adding users or functionalities might impact costs, so you can avoid unexpected expenses during rapid scaling. To manage the costs of high-volume data collection, define retention policies for telemetry data and archive older information in more affordable storage options. Proactive monitoring also reduces the financial risks associated with poor-quality supplier data.

Conclusion

Building a supplier portal that can scale alongside your business requires a solid foundation and a forward-thinking strategy. The key lies in combining flexible architecture, smart automation, clear governance, and ongoing performance tracking. Together, these elements prepare your portal to manage increasing supplier numbers, intricate workflows, and shifting demands effectively.

With the rapid growth of B2B eCommerce, portals designed for scalability have become essential. Features like self-service tools, no-code workflow engines, and role-based dashboards can simplify operations and reduce administrative burdens. In this environment, strategic collaboration becomes even more vital.

As Shawn Cady, Career Technologist at Clover, puts it:

"The evolution of supplier collaboration focuses not on doing more, but on achieving better, faster, and smarter results."

This perspective underscores the value of tools that provide real-time visibility across supplier tiers, automate routine tasks, and offer actionable insights for exceptions. Leverage AI's platform is tailored for this purpose, delivering predictive, exception-driven operations through AI-native orchestration in just 45–90 days.

Scaling supplier management effectively starts with selecting the right technology partner and committing to ongoing improvement. By applying strategies like microservices architecture, automated onboarding, and robust monitoring, you can create a portal that not only supports growth but actively accelerates it. These approaches ensure your supplier portal becomes a driving force for your business's success.

FAQs

How do multi-tier supplier portals enhance supply chain visibility?

Multi-tier supplier portals give businesses a clearer view of their entire supply chain - not just their immediate suppliers (Tier 1), but also Tier 2 and Tier 3 suppliers. This expanded visibility helps pinpoint potential bottlenecks or risks that could disrupt operations further down the line.

These portals work seamlessly with ERP systems, automating data collection and eliminating the need for manual tracking or isolated spreadsheets. With real-time updates and smooth communication across all supplier levels, businesses can tackle issues faster, minimize delays, and stay on top of regulatory and sustainability standards. As supply chains become increasingly intricate, having tools like these is crucial for staying agile and running efficiently.

What are the advantages of using a microservices architecture in supplier portals?

Opting for a microservices architecture in supplier portals offers flexibility and room for growth, making it a smart choice for businesses on the rise. Microservices break down a system into independent, modular components. Each one can be developed, deployed, and updated on its own, meaning businesses can respond to shifting supply chain demands without overhauling the entire system.

Scalability is another big win here. Since each service operates independently, you can adjust resources for individual components based on current needs. This ensures smooth performance, even as supply chains grow more complex. Plus, reliability gets a boost. If one service encounters an issue, it’s contained - preventing a domino effect across the entire system.

With smaller, dedicated teams managing specific services, updates and fixes roll out faster. This not only keeps things running efficiently but also strengthens the system's ability to handle challenges.

How can automation simplify supplier onboarding and communication?

Automation takes the hassle out of supplier onboarding and communication by tackling repetitive tasks, speeding up workflows, and ensuring precision. Using tools like AI, automated systems can verify credentials, evaluate risks, and confirm compliance - all in a fraction of the time it used to take. What once dragged on for weeks can now be wrapped up in just a few days. These systems also handle tedious jobs like document validation, data entry, and processing, cutting down on errors and reducing the need for manual follow-ups.

When it comes to communication, automation steps in with features like real-time updates, digital audit trails, and centralized supplier information through ERP system integration. Suppliers gain the ability to track order statuses, submit documents, and receive automatic notifications, which helps eliminate delays and constant back-and-forth. This smoother process not only resolves potential issues early but also fosters better operations and stronger supplier partnerships.

%202%20(1).png?width=50&height=50&name=20250501_1415_Professional%20LinkedIn%20Update_remix_01jt6gxkjmekavnvzsewk61z9w%20(1)%202%20(1).png)