Why End-to-end Purchase Order & SKU Management Increase Collaboration & Mitigate Disruptions

Right now, in some ways, the supply chain world is like a car with a manual transmission that can’t shift into a faster gear. Teams are exhausted as nearly every aspect of the supply chain has faced disruption over the last several years. As the global supply chain gets more connected over time, each disruption in a node of the supply chain can have severe knock-on impacts that hurt teams downstream. There needs to be as much proactive, visible, and real-time management in all facets of the supply chain to aid in sourcing information, providing actionable insights, and tools or platforms that are easily integrated into teams’ workflows with little to no interruption.

For supply chain procurement teams looking to procure items, manage POs, and manage the SKUs related to those items, end-to-end manual purchase order and SKU management hampers the supply chain “car” trying to get into a higher gear so teams can enable the vehicle to move swiftly to its destination.

It is the inability to gain end-to-end visibility of purchase orders and the Item Master, which contains all the key information about a particular item of inventory or materials from beginning to end that is hampering overall strategy, collaboration, and the ability to mitigate disruptions. An end-to-end management system that follows the Item Master t from the start to finish line can help solve those problems and put both the consumer and vendor in the fast lane.

From the Starting Line to the Checkered Flag

Imagine having a sharp-eyed co-pilot for every mile that the items and materials travel supply chain teams need to track. End-to-end, PO management enabled via a supply chain control tower platform allows the automation of the status of every phase of the PO to be within easy grasp, usually without needing a third party. At this moment, the process of generating PO status is very manual and involves phone calls and emails to your suppliers and freight forwarders, spending too much time on sourcing the information related to every PO and every SKU.

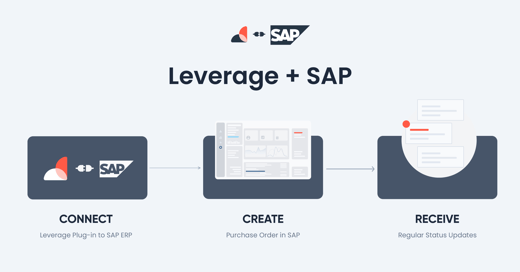

End-to-end supply chain, PO, and SKU management begins with procurement teams. It is where data logging and condition monitoring begins. Leverage, the ultimate control tower for supply chains, delivers automated, real-time status updates on all POs, which creates proactive workflows that drive the growth and scalability of its customers’ supply chains, and helps create workable, more optimal processes for PO and SKU management from the very beginning.

Purchase order management is an internal procurement process that makes sure every purchase is imperative, justified and optimized for costs. Entrenched PO management policies are vital in many organizations and help make sure that employees follow standard procedures before purchase orders are carried out.

However, as mentioned above, supply chain and raw material teams are struggling to manage PO status effectively, hampering the ability to know if inventory levels can meet future demand, as well as answering the age old question, “Where’s my stuff?” Teams need a new co-driver for end-to-end purchase order and SKU management.

Steering Past Obstacles of End-to-End PO and SKU Management

What keeps the transaction process from turning on a dime? Clarity and efficiency are two of the biggest roadblocks. Details like description, price, quantity, and delivery terms need to be clear and uniform with each order. In addition to that, there is the time, energy, and money that can often be wasted when there is no clear, consistent, quantifiable route taken. Without a purchase order, and more importantly without knowing the real-time status of any purchase order, the left hand can not know what the right hand is doing and there can be numerous steps needlessly taken during the transaction process.

Here are some of the challenges:

- Keeping a disparate and often physically distant group of colleagues on the same page.

- Assuring that everyone in the chain can clearly and easily comprehend the objective.

- Making sure that communication of each step is clear and simple.

- Providing the quality and speed that will keep ahead of the competition and sensing when it’s time to adapt to new technology advancements.

- Analyzing operating models and integration strategies to find what suits all parties.

- Spending too much time tracking down purchase orders and knowing exactly where an item is at all times.

- Keeping track of exact inventory levels in real time or knowing, to the SKU level, if the company can meet future demand or if a new order needs to be placed by the procurement team to fulfill the lack in inventory to meet demand.

With the assistance of Leverage, a clear and identifiable path — from order-creating to purchasing to shipping to receiving to record keeping — can be laid and errors like forgotten requests, unaware co-workers or supervisors and duplicated communication can be avoided.

Making Sure PO & SKU Management Runs at High-Performance

With a platform like Leverage taking care of end-to-end purchase order and SKU management, there are plenty of best practices to raise efficiency to its zenith. Things like making SKUs easy to understand, using naming conventions for SKUs according to purpose and not using characters that are not clear and easily understood by the supply chain team are just a few of the ways to make sure things all run smoothly.

There are other benefits to having a PO & SKU Management system:

- The elimination of manual entries which can lead to plenty of pitfalls like time spent waiting to receive orders and inputting information for purchase orders for split shipments. Also, with a reduction in data entry, there is also less of a chance of entry error.

- In addition to improving efficiency and costs, the ease of the platform can bring greater collaboration (between buyers and vendors, as well as among co-workers) that can make for more amicable working environments. This will enable teams to focus on big-picture, strategic initiatives such as how to improve overall customer experience.

- More resilience in the supply chain. With automated status updates around purchase orders, along with the ability to understand inventory levels in real time, teams are more proactive, collaborative, and able to confidently meet consumer demand.

- With the end-to-end management, the purchase order can be followed by all parties the whole way and help avoid the classic question of “where is my stuff?” or “what happened to the items I shipped?”

We Can Help You Finish First in the PO & SKU Management Race

For all parties involved — from the vendor to the shipper to the buyer — there are many dangerous curves and slippery spots throughout the ride. But end-to-end PO & SKU management can clear the way. With Leverage at the wheel, the journey can be a successful, smoother ride to the final destination. And in the process, you’ll never drop the ball on another purchase order. Ready to learn more? Schedule a demo with Leverage today.