How Real-Time ERP Data Reduces Supply Chain Delays

.png?width=50&height=50&name=julie-miller-square%20(1).png)

TL;DR: Real-time ERP systems eliminate delays caused by outdated batch processing by continuously updating data across inventory, procurement, manufacturing, and logistics. This improves supply chain visibility, automates decision-making, and reduces disruptions. Companies using real-time ERP report faster responses, fewer errors, and cost savings through better inventory management and supplier collaboration.

Supply chain delays often stem from fragmented systems, poor communication, and outdated inventory data. Real-time ERP systems solve these problems by providing live updates and centralizing data, enabling businesses to:

- Track inventory and shipments in real-time to prevent stockouts and overstocking.

- Improve supplier collaboration with automated updates and notifications.

- Use predictive analytics to anticipate and avoid disruptions.

- Automate processes like replenishment and scheduling for faster decision-making.

For example, companies like Hexion and Manroland Goss have reduced delays and improved efficiency by adopting real-time ERP. By integrating IoT and AI, these systems take supply chain management to the next level, ensuring immediate responses to issues and long-term cost savings.

ERP and its integration with Digital Supply Chain

Common Causes of Supply Chain Delays

Supply chain delays don’t happen in a vacuum. They often stem from fragmented systems, miscommunication, and outdated information that make it hard to address problems before they escalate. Let’s take a closer look at some of the main drivers behind these disruptions.

Data Silos and Limited Visibility

When supplier data is scattered across multiple systems - like ERP platforms, supplier management tools, financial software, and even spreadsheets - gaining a clear view of the supply chain becomes nearly impossible. Traditional ERP systems were designed for basic transaction management, not the unpredictable challenges of today’s markets.

Here’s the reality: 77% of enterprises don’t have real-time access to ERP data, and 46% of manufacturers lack the visibility needed to respond to supply chain changes effectively. Even worse, 65% of procurement leaders can’t see beyond their tier-1 suppliers. This means that if a tier-3 supplier experiences shipping delays, it often goes unnoticed until it’s too late to prevent disruptions.

Take Hexion, a specialty chemical manufacturer, as an example. In 2021, the company used process mining to uncover 10,000 process variations caused by disconnected data. These variations led to frequent route changes, which increased delivery times. By addressing these silos, Hexion reduced route changes by 45% and cut the time from credit hold release to shipment from 11 days to just 5 days through automated notifications. Centralizing data with real-time ERP integration can eliminate such bottlenecks.

But even with better visibility, poor communication among suppliers can amplify delays.

Poor Supplier Communication

Manual workflows and weak collaboration create ripple effects throughout the supply chain. In fact, 30% of manufacturers say inadequate supplier collaboration disrupts operations. On top of that, supply chain professionals spend nearly 14 hours each week - almost two full workdays - manually tracking data.

Without real-time data sharing, isolated teams can make changes that go unnoticed until they cause larger problems. This lack of coordination is why 31% of manufacturing executives rank the inability to fulfill contracts as a top concern.

A case in point: After merging into TD SYNNEX, Tech Data analyzed millions of transactions and found that 30% of purchase orders faced price changes or cancellations due to communication issues. By addressing these gaps, they reduced the price change ratio by 27% in six months and cut their procure-to-pay cycle time by 57% within a year.

Beyond communication breakdowns, inaccurate inventory data can further complicate things.

Inventory Errors and Stockouts

Errors in inventory data can trigger a domino effect, disrupting production schedules and order fulfillment. Many material planners still rely on quarterly manual reviews - often using Excel spreadsheets - instead of real-time data. This outdated approach leads to incorrect safety stock calculations, resulting in either stockouts or excess inventory.

The stakes are high. 85% of ERP professionals believe outdated data leads to poor decisions and bad business outcomes. And for Consumer Packaged Goods (CPG) brands, supply chain issues could cost up to $800 billion in lost growth over five years.

Manroland Goss, a printing press manufacturer, faced similar challenges. They managed lead times and safety stock using manual SAP exports and quarterly Excel reviews, which frequently caused stockouts and overstocking. By switching to daily automated safety stock reviews for over 10,000 materials and $17M in spend, the company saw immediate improvements within a month and kept their SKUs up-to-date. Real-time ERP data allows for continuous, automated reviews that prevent outdated calculations from causing havoc.

"The supply chain team is attempting to drive uphill, but visibility is low, and uncertainty is high."

- Lora Cecere, Founder, Supply Chain Insights

The solution lies in modernizing supply chains. Currently, 76% of supply chain executives lack a predictive view of supply and demand, forcing 92% to rely on gut instincts instead of data-driven decisions. Real-time ERP integration offers a way forward by centralizing data, automating communication, and providing the insights needed to stay ahead of disruptions.

How Real-Time ERP Data Addresses Supply Chain Problems

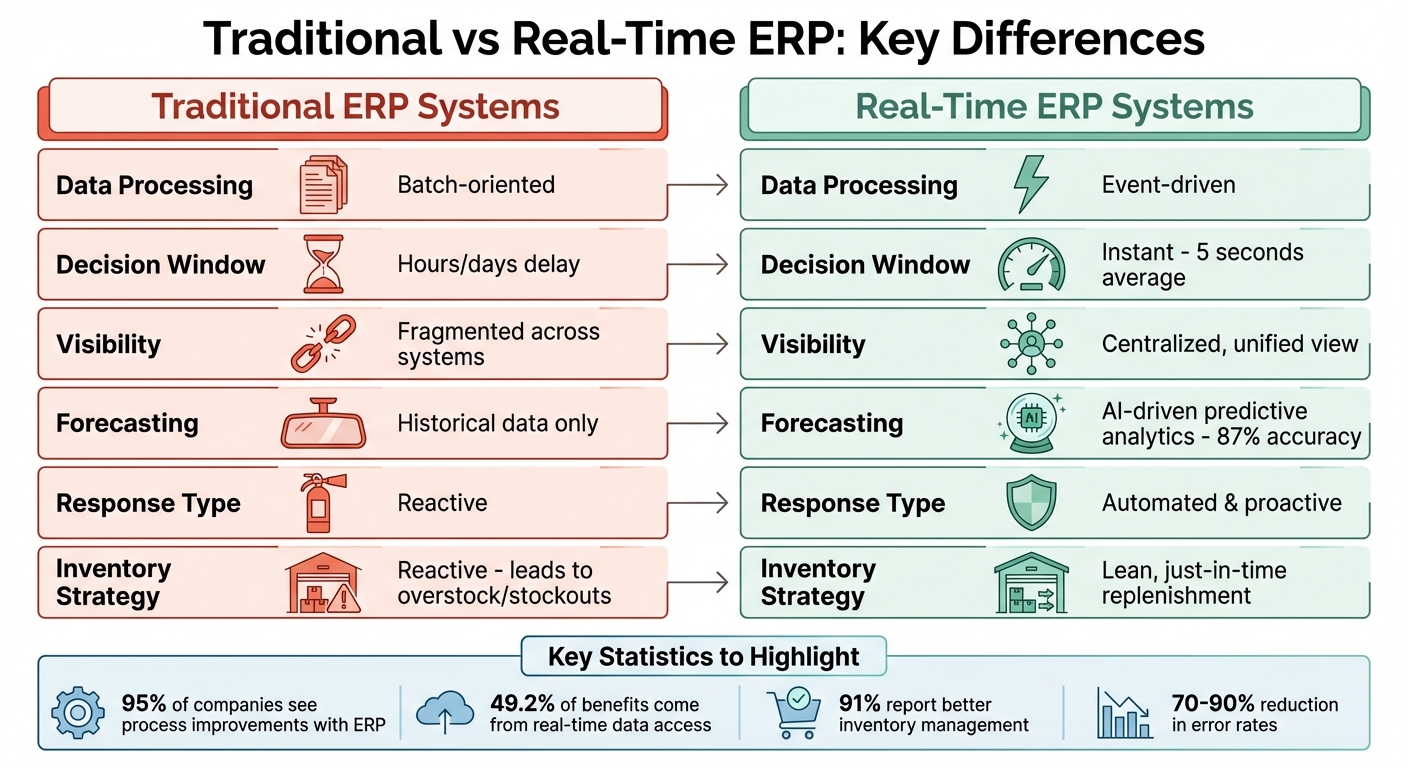

Traditional ERP vs Real-Time ERP Systems Comparison

Real-time ERP systems are changing the game for supply chain management by bringing together scattered data and enabling fast responses. These systems continuously process information, allowing managers to spot and address issues almost instantly.

The difference between older systems and real-time ERP is striking. Traditional systems process data in batches, often leading to delays, while modern ERP systems work continuously. For example, if shipments are delayed or inventory levels drop too low, automated alerts are triggered immediately.

The results are clear. Reports show that 95% of companies see process improvements after adopting ERP solutions. Even more compelling, 49.2% of the benefits come directly from real-time data access. By removing delays between detecting and resolving issues, businesses can prevent minor problems from escalating into major disruptions. This constant data flow supports improvements in areas like inventory tracking, supply chain visibility, and planning.

Centralized Inventory Tracking

Real-time ERP systems give businesses an accurate, up-to-the-minute view of inventory levels across all locations. Instead of relying on outdated spreadsheets, companies can monitor stock movements in real time across warehouses, distribution centers, and retail stores.

The impact is substantial. A staggering 91% of organizations report better inventory management after implementing ERP solutions. With a single, reliable source of data, businesses know exactly what’s in stock, what’s in transit, and what’s already committed to customer orders. When inventory hits critical levels, the system can automatically trigger replenishment orders or reallocate stock to avoid production delays.

Complete Supply Chain Visibility

Real-time ERP doesn’t stop at inventory - it provides a full view of the entire supply chain. By combining data from ERPs, IoT devices, and logistics providers into one platform, companies gain insights across their own operations and those of their supply chain partners. Currently, only 22% of businesses take proactive steps to achieve this level of visibility, leaving many stuck in reactive modes. Real-time tracking helps identify issues like rising transportation costs or potential equipment failures before they disrupt production.

IoT sensors play a big role here, feeding live data on equipment performance, vehicle locations, and environmental factors straight into the ERP system. Logistics providers, for instance, can generate over 500,000 data points per hour, which can then be analyzed for actionable insights. Modern solutions also establish a "canonical linkage", creating a clear chain of custody that ties purchase orders to shipments, handling units, and individual items.

Coordinated Planning and Scheduling

Real-time data transforms demand forecasting and production scheduling by merging live sales data with current market conditions. Instead of relying solely on past trends, businesses can use AI-driven predictive analytics to better anticipate risks and adjust production plans. In one experiment, AI forecasting accurately predicted 87% of late orders before they even shipped. This allows companies to shift resources, adjust schedules, or prioritize shipments before delays affect customers.

Sharing real-time data also keeps suppliers and logistics providers on the same page. When production schedules change or demand spikes without warning, the entire supply chain gets updated instantly, avoiding the communication gaps that hinder 30% of manufacturers in collaborating with suppliers.

| Feature | Traditional Systems | Real-Time ERP |

|---|---|---|

| Data Processing | Batch-oriented | Event-driven |

| Decision Window | Hours/days delay | Instant |

| Visibility | Fragmented | Centralized |

| Forecasting | Historical only | AI-driven |

| Response | Reactive | Automated |

These advancements tackle key supply chain challenges head-on. They break down data silos, improve communication with synchronized updates, and prevent inventory errors through constant monitoring. Real-time ERP integration marks a major shift in how supply chains operate, moving businesses from reacting to problems to actively preventing them.

Methods for Reducing Supply Chain Delays

Using real-time ERP systems alongside automation, IoT, and supplier tracking tools can transform supply chain management. Instead of constantly reacting to problems, these technologies allow for proactive solutions.

Automated Alerts and Notifications

Modern ERP systems excel at monitoring critical data and sending immediate alerts when something goes off track. For example, if a pallet misses its scheduled sort by 30 minutes, the system can automatically create a rebooking task. Similarly, if a supplier fails to provide necessary documentation before pickup, automated reminders are sent right away. This early detection highlights issues like spikes in dwell time or missing Advanced Shipping Notices before they impact customers.

Real-time event processing significantly reduces response times - down to about five seconds, compared to hours or even days with older batch systems. AI-powered alerts can even predict delays up to 72 hours in advance by analyzing factors like weather, port congestion, and traffic. This allows teams to reroute shipments proactively, avoiding last-minute scrambles.

In October 2024, Festo introduced its Automation Experience (AX) Platform, which combines IoT with SAP and Oracle ERP systems. By using AI-driven sensors to monitor equipment health in real time, Festo managed to cut downtime by 20% and reduce waste by 50%. A key feature of the platform was its ability to set specific thresholds, avoiding alert fatigue by grouping similar events and prioritizing actionable notifications.

IoT integration complements these alerts by continuously feeding live data into ERP systems, ensuring that every aspect of the supply chain is monitored in real time.

IoT Integration for Live Monitoring

IoT sensors have revolutionized supply chain management by offering continuous, near real-time visibility. Devices like RFID tags, GPS trackers, and temperature sensors feed live data into ERP systems, creating a digital twin of warehouse and logistics operations. By mid-2024, 62% of U.S. manufacturers were using IoT for real-time tracking, marking an 18% increase from the previous year.

A great example comes from Dutch manufacturer Boers & Co, which integrated Epicor IoT with Microsoft Azure in April 2024. Wireless sensors identified early signs of machine wear, allowing the company to schedule maintenance proactively and drastically reduce unplanned downtime. By processing data closer to the source (at the edge), latency was minimized, enabling quicker automated responses.

Walmart also leveraged IoT through a partnership with IBM's Hyperledger blockchain to track leafy greens from farm to shelf. This system reduced the time needed to trace a product’s origin from seven days to just 2.2 seconds, a game-changer for handling contamination events.

"IoT-based supply chain visibility is the solution that can not only benefit operational efficiency but also reinforce the risk management strategies, thus ensuring a competitive edge in any unstable global markets."

– Irshadullah Asim Mohammed, Supply Chain Project Manager, FuelCell Energy Inc.

Supplier Performance Tracking

Tracking supplier performance is just as important as real-time alerts and IoT monitoring. Instead of relying on outdated spreadsheets or quarterly reviews, modern platforms allow companies to monitor delivery times, quality metrics, and responsiveness as they happen. These platforms integrate live data with supplier risk scores, contract details, and regional restrictions to flag potential issues before they escalate.

AI-driven tools enhance this process by automating follow-ups with suppliers, improving engagement, and providing real-time insights to prevent delays. Steve Andrews, Director of Systems Control, highlighted the impact of such tools:

"Leverage saves each of our buyers at least 50% of their time every week, and we were able to reduce our planned headcount".

Supplier collaboration portals further streamline operations by giving vendors access to RFQs, purchase orders, and performance metrics in real time. This improves communication and shortens lead times.

In 2024, a global fast-food chain adopted AI-driven supplier health monitoring to address Brexit-related risks. By identifying alternative European suppliers in real time, the chain reduced network distance by 25% and saved €3.2 million annually. The system analyzed millions of data points, from geopolitical events to social media trends, providing a comprehensive view of supplier risks that went far beyond simple credit checks.

AI-based forecasting models integrated into these systems have shown an 87% accuracy rate in predicting late orders before they even ship. With 70% of Chief Procurement Officers reporting an increase in procurement risks, real-time supplier performance tracking is now a critical component of resilient supply chains.

sbb-itb-b077dd9

Measurable Benefits of Real-Time ERP Integration

Real-time ERP integration delivers measurable improvements in efficiency and cost management. By providing instant visibility into supply chain operations - from inventory levels to supplier performance - businesses can shift from reactive approaches to proactive strategies, resulting in faster decisions, reduced costs, and smoother operations.

Better Efficiency and Lower Costs

Real-time ERP integration eliminates the need for manual processes that are prone to errors, replacing them with automated workflows. This shift not only saves time but also cuts costs significantly. In fact, custom integrations often pay for themselves within 6–12 months by streamlining repetitive tasks into automated processes.

"Custom integrations often pay for themselves quickly - example: replacing 40 hours/week of manual CRM-to-billing work saved $78K/year versus a $15K implementation cost (≈520% ROI)."

– Ken Peluso, Fractional CTO

Automation improves data accuracy, reducing error rates by 70–90%. This minimizes costly mistakes, such as incorrect shipments or failed invoices, and avoids audit exceptions. Additionally, real-time integration shortens the order-to-cash cycle, improving cash flow. When GPS data is integrated, transportation routes are optimized, cutting fuel costs and reducing carbon emissions by eliminating unnecessary delivery attempts.

| Metric | Before Real-Time ERP Integration | After Real-Time ERP Integration |

|---|---|---|

| Data Visibility | Fragmented and siloed across departments | Unified, enterprise-wide view on one dashboard |

| Reporting Speed | Weekly or monthly updates | Instant, real-time reporting |

| Inventory Strategy | Reactive, leading to overstock or stockouts | Lean, just-in-time replenishment |

| Decision Basis | Historical data and guesswork | Real-time analytics and data-driven insights |

| Issue Response | Delayed identification of problems | Real-time alerts and immediate action |

| Logistics | Manual processes and static routing | Automated dock assignments and GPS-optimized routes |

Better Decision-Making with Live Data

Real-time data empowers businesses to move from reactive decision-making to proactive strategies. For instance, real-time event processing reduces decision latency to an average of just five seconds. This enables teams to address issues as they arise, rather than discovering them after the fact.

Modern logistics operations generate over 500,000 data points per hour, and real-time processing turns this overwhelming flow of information into actionable insights. Using machine learning models like XGBoost, IoT-enabled ERP systems can achieve predictive accuracy as high as 98.51%.

The benefits extend beyond speed. Real-time analytics enable proactive risk management, such as identifying alternative suppliers or adjusting manufacturing processes to handle disruptions. This is especially crucial given that 46% of manufacturers lack the visibility and agility needed to respond effectively to supply chain changes.

Steps to Implement Real-Time ERP Data Integration

Achieving these benefits requires a well-planned implementation strategy. A structured approach ensures minimal disruption while maximizing the value of integration. Start with a 2-week discovery phase to map existing data flows and define service-level agreements. This step highlights operational gaps in areas like planning, procurement, and logistics that the integration should address.

Next, conduct a 4–6 week pilot program focusing on high-impact workflows, such as billing and inventory management, where delays directly affect revenue. Prioritize automations that replace manual tasks costing $30–$75 per hour, as these offer the quickest returns. Middleware with retry logic and error handling can help manage API rate limits and avoid data issues.

Before scaling up, run pilot tests using real data in a test environment to validate workflows and integrations. Ensure data migration protocols are in place to cleanse and standardize existing information, maintaining accuracy from the start. Configure automated alerts for inventory thresholds and supplier delays to enable immediate responses.

Finally, invest in thorough team training to address both technical skills and new processes. Track baseline metrics like reporting speed, error rates, and manual labor hours for 30–90 days before integration to measure improvements post-implementation. This data-driven approach ensures clear evidence of value and supports continued investment in real-time ERP capabilities.

Using AI to Improve Real-Time ERP Capabilities

AI is changing the game for real-time ERP systems, turning them from simple data trackers into active decision-making tools. Traditional ERP systems are great for visibility, but platforms like Leverage AI take it a step further by automating supplier communications and removing manual bottlenecks. This shift helps reduce supply chain delays and makes processes more efficient.

AI-Powered Purchase Order Automation

Did you know that 57% of procurement leaders still rely on manual purchase order processing? This outdated method often leads to delays and errors. AI-powered automation is a game-changer here. It extracts data from various email formats and feeds it directly into ERP systems. The result? Processing times drop by up to 80%, and errors are reduced by 70%.

Leverage AI's document parsing technology makes this process even smoother. Teams can respond instantly using automated tools integrated into platforms like Outlook or Gmail. For instance, the system can automatically send reminders to suppliers when essential documents - like an Advanced Shipping Notice (ASN) expected 12 hours before pickup - are missing. These proactive measures can prevent production delays and even improve profit margins by 5–10%.

Real-Time Supply Chain Visibility

AI platforms excel at pulling together data from ERPs, third-party logistics providers, and IoT devices into a single, easy-to-use dashboard. This is crucial because 54% of supply chain leaders report daily disruptions due to a lack of real-time data. With modern logistics generating over 500,000 data points per hour, tools like those from Redwood Logistics transform this overwhelming volume into actionable insights.

Leverage AI's platform uses zero-copy integration to access billions of records in real time without duplicating data. This ensures supplier communications are always based on the latest inventory and capacity details. Companies adopting these tools have seen over a 20% reduction in expedited shipments. The system also automates exception handling - if a pallet is missed or an ETA changes, it rebooks tasks and notifies suppliers automatically. Customizable workflows further streamline these processes, making integration with existing ERP systems seamless.

Customizable Workflows and ERP Integration

Leverage AI's tools are designed to work with existing ERP systems, improving efficiency without the need for a complete overhaul. For example, its workflows guide shipments through every stage - planned, tendered, in transit, and delivered - while enforcing automated rules. A great real-world example is Coke One North America (CONA), which used these tools to integrate SAP data across its enterprise in November 2022. This integration boosted supply chain transparency and sped up responses to critical issues.

The platform also normalizes inconsistent data inputs, mapping different status labels (like "Gate-out" and "COL") to a unified "Departure" status for better data integrity. Beyond that, AI agents can take real-time actions like triggering purchase orders, rerouting shipments, or adjusting inventory levels - all without human involvement.

One industry report highlights the importance of real-time data for these AI agents:

"Autonomous AI agents require real-time data to execute accurate decisions when tariff structures shift rapidly".

And with zero-copy integration:

"doesn't just improve response times incrementally - it fundamentally changes competitive dynamics by collapsing the timeline between disruption and action from days to hours".

This combination of automation, real-time data access, and seamless ERP integration is reshaping how businesses handle supply chain challenges.

Conclusion

Real-time ERP integration is reshaping supply chain management by bringing together finance, procurement, manufacturing, and logistics into a single, reliable data source. This consolidated view allows teams to track inventory across multiple locations, monitor shipments as they happen, and address bottlenecks before they grow into larger problems.

Here’s the impact in a nutshell: businesses using real-time ERP systems see shorter lead times, better delivery schedules, and reduced costs that directly improve profit margins. Enhanced inventory tracking prevents both shortages and overstock, while more accurate order fulfillment speeds up deliveries and improves customer satisfaction. Take the example of a global chemicals distributor that cut expedited shipments by over 20% after implementing a real-time digital twin of its $3 billion supply chain.

But the benefits don’t stop at operational efficiency. Real-time data also drives smarter, automated decision-making. With 54% of supply chain leaders dealing with daily disruptions and data delays costing companies millions annually in working capital, the stakes are high. Traditional ERP systems provide visibility, but AI-powered platforms go a step further - automating supplier communication, predicting potential disruptions, and enabling immediate action. As Orkestra aptly put it:

"The value of real-time data to business operations can't be overstated. It provides supply chain managers with the ability to maintain visibility and empowers them with the information to make business-enhancing decisions without delay." - Orkestra

If you're looking to eliminate reactive delays and create a more agile supply chain, AI-powered tools like Leverage AI can take your real-time ERP integration to the next level. Features like automated purchase orders, supplier performance tracking, and seamless ERP connectivity transform raw data into actionable insights. This means cutting the response time to disruptions from days to mere hours.

The takeaway? Real-time ERP data isn't just an advantage - it's essential for staying competitive.

FAQs

How does real-time ERP data enhance collaboration with suppliers?

Real-time ERP data keeps all supplier communications and updates in one place, making it easier to access important information quickly and securely. By eliminating the back-and-forth confusion often caused by miscommunication, it helps reduce delays and keeps operations running smoothly.

Features like automated workflows, performance tracking tools, and proactive alerts allow businesses to simplify processes, monitor supplier performance, and tackle problems before they grow. This improved transparency and efficiency help build stronger, more dependable relationships with suppliers.

How does AI improve real-time ERP systems for supply chain management?

AI brings a transformative edge to real-time ERP systems by automating essential supply chain tasks like demand forecasting, tracking supplier commitments, and spotting anomalies. This automation minimizes delays, boosts precision, and simplifies decision-making processes.

With predictive insights and the ability to address issues before they escalate, AI equips businesses to handle potential disruptions swiftly. It also fosters stronger supplier relationships and provides real-time transparency, making supply chain operations smoother and more adaptable.

How does real-time ERP data help prevent inventory errors and stockouts?

Real-time ERP data is a game-changer for managing inventory. It provides up-to-the-minute visibility into stock levels, supply chain operations, and demand patterns. This level of insight helps businesses spot discrepancies or potential shortages fast, allowing them to respond by adjusting orders or redistributing inventory across locations.

With accurate, real-time data, ERP systems also enhance demand forecasting, making it easier to avoid overstocking or running out of key items. These systems monitor supplier performance and delivery schedules, so businesses can act quickly if delays or issues arise. The result? Inventory levels that align closely with actual demand, reducing errors and keeping stockouts to a minimum.

.png?width=50&height=50&name=julie-miller-square%20(1).png)