AI Trends in Supplier Feedback Analysis 2025

.png?width=50&height=50&name=julie-miller-square%20(1).png)

TL;DR:

AI is reshaping supplier feedback analysis by enabling faster insights, predictive risk management, and improved supplier relationships. Key trends include automated data processing, real-time sentiment analysis, and predictive analytics, with AI reducing manual tasks and decision-making time significantly. However, challenges like data quality and balancing automation with human oversight remain critical.

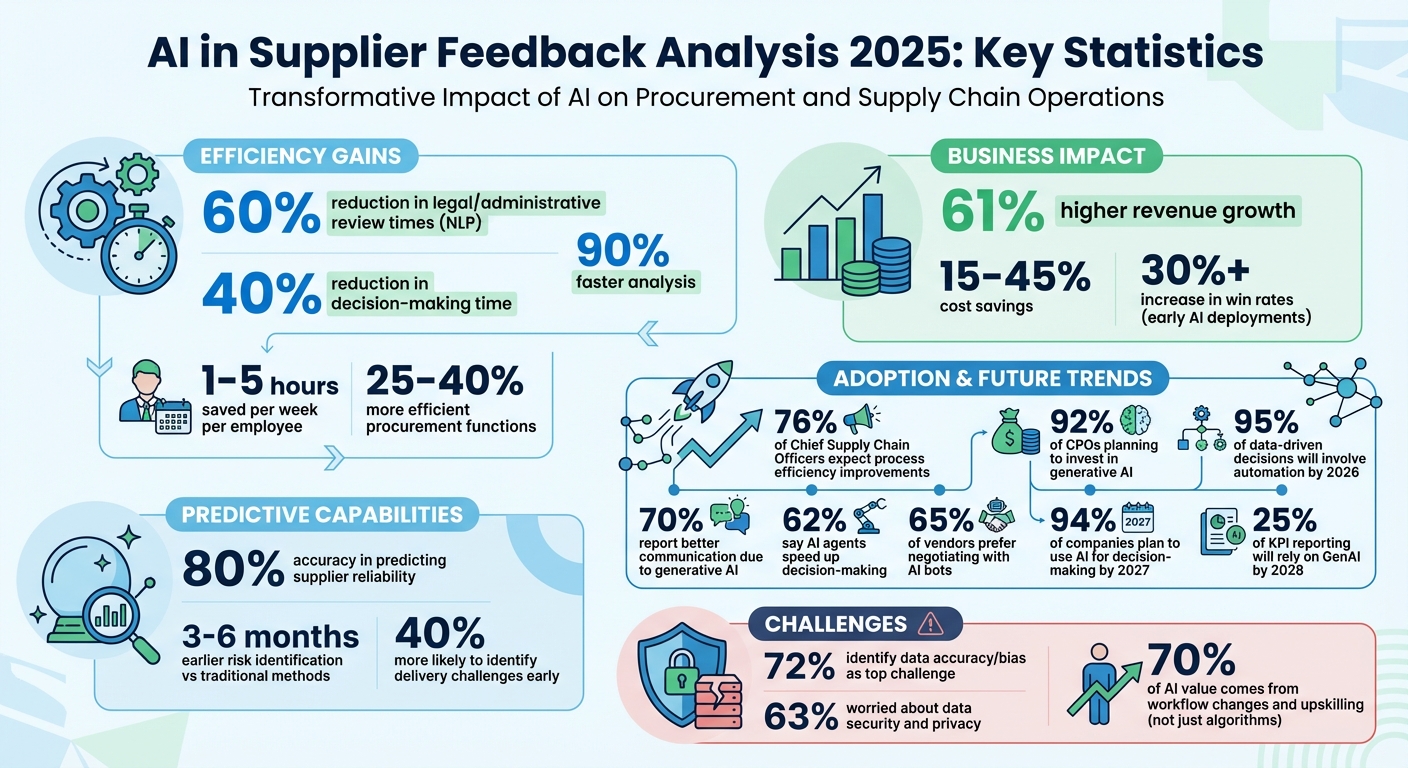

AI Impact on Supplier Feedback Analysis: Key Statistics and Benefits 2025

Automate your Supplier Evaluation with Pipefy AI Agents

AI in Supplier Feedback Analysis: Key Insights

AI is transforming how businesses handle supplier feedback by processing data faster and providing actionable insights. Here’s what’s happening:

- Automated Feedback Processing: AI systems now handle tasks like analyzing supplier emails, contracts, and performance metrics. Tools like NLP reduce review times by up to 60%.

- Sentiment Analysis: AI detects tone and intent in supplier communications, helping businesses identify and address issues early.

- Predictive Analytics: Machine learning models forecast risks months in advance, improving supply chain reliability by 80%.

- Improved Communication: AI-powered tools streamline supplier interactions, with bots negotiating terms and automating updates.

Challenges

- Data Quality: Poorly structured or inconsistent data limits AI’s effectiveness.

- Human Oversight: Over-reliance on automation risks losing critical human expertise in decision-making.

Why It Matters

AI-driven tools are cutting decision cycles from weeks to minutes, saving costs (15–45%) and boosting revenue growth (61%). By 2028, 25% of KPI reporting will rely on generative AI, signaling a shift toward automated, data-driven supply chain management.

AI is a game-changer, but thoughtful implementation and maintaining human involvement are key to long-term success.

Top AI Trends in Supplier Feedback Analysis for 2025

Automated Feedback Collection and Processing

By 2025, AI systems are set to take on more complex and independent tasks, acting as a virtual workforce. These advanced AI agents go beyond simple automation - they negotiate with suppliers, adjust stock levels, and manage communications seamlessly. In fact, 76% of Chief Supply Chain Officers expect process efficiency to improve as AI takes over repetitive tasks, completing them far faster than humans.

Natural Language Processing (NLP) is revolutionizing how businesses handle contracts, proposals, and supplier emails. With its ability to extract key terms automatically, NLP is cutting legal and administrative review times by up to 60%. Additionally, AI systems now pull financial data, compliance records, and performance metrics directly from public databases and supplier portals, eliminating the need for manual spreadsheet requests. These systems also draft personalized supplier communications and summarize large volumes of feedback into actionable insights.

Meanwhile, drones, mobile robots, and smart sensors are autonomously capturing real-time inventory and operational data. This "ambient invisible intelligence" ensures that feedback analysis systems always work with up-to-date information, reducing the need for human involvement.

Together, these advancements are laying the groundwork for more sophisticated supplier insights.

Real-Time Sentiment Analysis and Supplier Insights

With data collection becoming more advanced, AI is now better equipped to refine qualitative insights. It can detect tone, intent, and emotion in supplier communications, offering a deeper understanding of feedback. By analyzing unstructured data from emails, call summaries, social media, and support tickets, AI uncovers patterns that might go unnoticed by human analysts. Early AI deployments have already increased win rates by over 30% in commercial ecosystems.

Beyond identifying issues, AI provides actionable suggestions, such as prioritizing specific workflow steps or offering loyalty rewards to repair strained relationships. Organizations using AI for feedback analysis report saving one to five hours per week per employee, while also reducing decision-making time by up to 40%.

AI also pinpoints the root causes of problems, distinguishing between technical glitches and pricing concerns, enabling targeted solutions instead of broad responses. The rise of multimodal AI - capable of analyzing text, images, audio, and video simultaneously - ensures a more comprehensive understanding of supplier sentiment.

Predictive Analytics for Supplier Performance

Predictive analytics is taking supplier feedback and performance management to the next level by enabling proactive risk management. Machine learning models now identify risks 3–6 months earlier than traditional methods by analyzing subtle changes in payment patterns, communication habits, and operational metrics. These models evaluate hundreds of variables, including historical performance and external market trends, to predict supplier reliability with 80% accuracy, even estimating which suppliers will meet delivery targets months in advance.

AI-powered digital twins and simulations have become essential tools for procurement leaders. These systems allow for "what-if" scenario modeling, exploring the effects of events like geopolitical disruptions, material shortages, or labor strikes on supply chains. This shift from reactive problem-solving to proactive management helps identify risks in real-time. By 2027, 94% of companies plan to use AI or GenAI for decision-making and system-driven recommendations.

"Agentic AI operating models proactively respond to disruptions, make forecasts more accurately, and provide greater visibility across supply chain ecosystems." - IBM Institute for Business Value

Predictive models are now incorporating unconventional data sources - such as weather reports, market indexes, and geopolitical event tracking - to improve forecast accuracy. By 2026, 95% of data-driven decisions are expected to involve at least some level of automation, allowing procurement teams to focus on strategic relationship management rather than day-to-day operations.

sbb-itb-b077dd9

How AI Improves Supplier Relationships

Better Communication with AI-Powered Tools

AI is reshaping the way manufacturers and suppliers interact, making communication faster and more efficient. In fact, 70% of Chief Supply Chain Officers have reported better communication due to generative AI. Instead of waiting days for email replies or arranging lengthy calls to discuss order changes, AI assistants now provide instant responses to supplier inquiries. They also deliver continuous updates on demand forecasts and inventory requirements.

One standout improvement is in automated negotiations. A surprising 65% of vendors have expressed a preference for negotiating with AI-powered bots over human employees. These bots simplify complex tender processes, negotiate costs and terms, and drastically reduce the time it takes to finalize agreements. Additionally, 62% of supply chain leaders say AI agents embedded in workflows speed up both decision-making and communication.

AI also plays a critical role in identifying potential risks. Using Natural Language Processing (NLP), AI tools analyze supplier emails for patterns, response times, and sentiment. This helps flag early warning signs, such as a shift from collaboration to disengagement or potential delivery issues. These tools can identify suppliers that are 40% more likely to face delivery challenges, allowing manufacturers to address concerns before they escalate. This proactive approach reflects the broader trend of creating smarter, more integrated supply chains.

Platforms like Leverage AI integrate these capabilities directly into ERP systems, automating follow-ups and providing real-time updates. Features like AI document parsing and email-based smart purchase orders streamline communication, while still allowing human oversight for more complex decisions. These improvements feed into real-time performance scorecards, enhancing overall supplier relationships.

Data-Driven Supplier Scorecards

Improved communication is the foundation for more transparent and data-driven supplier evaluations. Traditional static scorecards are being replaced with real-time, dynamic profiles. AI agents now pull data continuously from ERP systems, quality management tools, and even external news sources, shifting evaluations from being reactive to predictive.

This shift builds trust by offering clear, measurable metrics - such as defect counts paired with tagged feedback like "responsiveness" or "innovation." Conversational AI co-pilots take this a step further by explaining, in plain language, why a supplier received a specific ranking. This clarity allows manufacturers to address performance gaps collaboratively.

"AI systems don't get tired, distracted, or biased like human analysts. They consistently apply the same analytical rigor to every supplier evaluation." – Esgrid

Consistency is key here. By 2028, 25% of KPI reporting in supply chains is expected to rely on GenAI models. This makes standardized, machine-readable data essential. Suppliers now share structured performance data, creating a single source of truth that supports synchronized decision-making. Dynamic scorecards, combined with real-time communication, form a seamless AI-driven feedback loop.

Accountability is another major advantage. AI-generated risk summaries can reduce supplier review cycles from weeks to mere minutes. These summaries include decision logs and data lineage, clearly showing why a supplier was flagged. This objective data transforms potentially tense performance discussions into opportunities for collaborative problem-solving.

Challenges in Adopting AI for Supplier Feedback

Data Quality and Integration Issues

Despite the fact that 92% of Chief Procurement Officers are planning to invest in generative AI, only 37% have actually deployed it as of late 2024. This gap between ambition and action boils down to one major hurdle: the quality of data.

Supplier data often exists in silos, riddled with inconsistent naming conventions and fragmented relationships that confuse AI systems. Add in manual data entry, and the problem gets worse - missing fields, duplicate records, and inconsistencies lead to flawed AI-driven insights. Traditional supplier scorecards don’t help much either. These tools often mix numerical KPIs with subjective comments, which AI struggles to interpret without proper data normalization.

"AI-based intelligent analytics can provide meaningful inputs for key decisions only if the underlying data is accurate and comprehensive." – Deloitte

The statistics back this up: 72% of executives identify data accuracy or bias as a top challenge in implementing AI for supply chain operations. Meanwhile, 63% of supply chain leaders are worried about data security and privacy. On top of that, many companies face difficulties integrating AI with older, on-premises systems, creating additional barriers around interoperability and security.

The solution lies in data normalization. Large Language Models (LLMs) can help by standardizing supplier names, cleaning up duplicates, and making data more consistent. Reworking supplier scorecards into machine-readable formats is another step forward. For example, instead of vague fields like "Quality Rating (1–5)", businesses can use specific metrics such as "Defect ppm + text summary of top 3 issues". Assigning unique, stable identifiers to each supplier across all systems is also critical to avoid AI confusing similar entities. For missing information, generative models can even be trained to fill gaps, like estimating prices or units of measure based on existing patterns.

These challenges underscore the importance of integrating AI thoughtfully while preserving human judgment - a balance explored in the next section.

Balancing Automation and Human Oversight

AI excels at processing supplier feedback at lightning speed, but speed without oversight can introduce new risks. The real challenge is finding the right balance between automation and human expertise. In fact, 76% of executives expect AI to improve efficiency, freeing employees to focus on more strategic, real-time analysis instead of repetitive tasks.

This shift requires procurement professionals to evolve their roles - from data processors to strategic decision-makers who collaborate with AI tools. Just as past advancements improved communication and processing speed, keeping human oversight ensures AI remains a tool to enhance, not replace, human expertise. To achieve this, AI systems need built-in guardrails. Recommendations should be both auditable and easy for human planners to override. Additionally, AI tools must provide clear, natural-language explanations for their feedback, helping experts verify the logic behind decisions.

"We needed to think about gen AI as a team member, a new colleague that needs to be trained. We needed to give it the business context and provide feedback on its decisions so it could improve." – Knut Alicke, Leader of McKinsey's Supply Chain Executive Academy

One growing concern is "learning and experience loss." Over-reliance on AI for tasks like supplier risk assessment could erode critical human skills over time. To counter this, organizations must invest in data literacy training, ensuring teams are equipped to intervene effectively during disruptions. Striking the right balance between automation and oversight can lead to significant efficiency gains and financial benefits.

Platforms like Leverage AI are tackling these challenges head-on. By integrating directly with ERP systems, they automate routine tasks like follow-ups while keeping humans involved in complex decision-making. These platforms enable real-time tracking of supplier performance and make procurement functions 25% to 40% more efficient. This approach lets businesses harness the power of AI while preserving the judgment and relationship-building skills that only humans can bring to the table.

Conclusion: The Future of AI in Supplier Feedback Analysis

Key Takeaways from 2025 AI Trends

AI has completely reshaped how supplier evaluations and supply chains operate. Tasks that once required weeks of manual effort - like sentiment analysis and risk detection - are now handled in real time, cutting decision cycles down to minutes. The numbers speak volumes: 61% higher revenue growth, 15–45% cost savings, and 90% faster analysis demonstrate how transformative AI has become.

The rise of Agentic AI signals a leap forward. Unlike traditional query-based tools, these advanced systems can autonomously manage intricate tasks such as supplier negotiations and dynamic sourcing. By 2028, 25% of KPI reporting in supply chains will rely on generative AI models, and by 2026, 95% of data-driven decisions will involve some level of automation.

"Agentic AI supercharges supply chain automation, delivering efficiency beyond human capacity, and taking growth to the next level." – IBM Institute for Business Value

These advancements highlight the importance of adopting AI strategically to stay competitive and unlock its full potential.

Adopting AI for a Smarter Supply Chain

For organizations looking to embrace AI, the focus must extend beyond technology to include their people. Studies show that 70% of AI's value comes from changes in daily workflows and upskilling teams, rather than the algorithms themselves. To succeed, start with a digital maturity assessment, identify high-impact areas, and establish strong governance before scaling AI initiatives.

FAQs

How does AI enhance supplier communication and negotiation?

AI is reshaping supplier communication by taking over repetitive tasks and offering real-time insights. For instance, it can sift through emails, chat logs, and ERP notes to pinpoint critical issues, gauge sentiment, and recommend effective follow-up responses. This reduces miscommunication and ensures conversations stay productive. Tasks like sending reminders, confirming order updates, and managing performance dashboards become more efficient, freeing procurement teams to focus on meaningful, strategic discussions instead of administrative work.

When it comes to negotiations, AI steps up with predictive analytics that simulate pricing and delivery scenarios. This helps buyers anticipate outcomes and approach negotiations with greater confidence. It also flags potential risks, such as supplier capacity constraints or geopolitical challenges, allowing for proactive adjustments. By transforming raw data into actionable insights, AI not only strengthens supplier relationships but also enables quicker, smarter decision-making.

What challenges do companies face when using AI for supplier feedback analysis?

Implementing AI for supplier feedback analysis isn't without its hurdles. One prominent challenge is data quality. AI can only be as effective as the data it processes, and many organizations grapple with issues like incomplete, inconsistent, or outdated supplier information. On top of that, legacy IT systems and scattered data silos often complicate the integration and analysis of real-time feedback. Addressing these issues may require a significant overhaul of existing infrastructure.

Another roadblock is the skills gap. Successfully leveraging AI requires a combination of expertise: skilled data scientists to manage AI models and procurement teams equipped to interpret and act on AI-driven insights. Lastly, ensuring that AI initiatives deliver clear and measurable ROI is essential. Without tangible results that align with business objectives, leadership may hesitate to commit to these investments.

AI solutions can help tackle these challenges by automating data collection, seamlessly integrating with ERP systems, and delivering real-time insights into supplier performance. This empowers businesses to transform feedback into actionable strategies with minimal effort.

How can companies effectively combine AI automation with human expertise in supply chain management?

To blend AI automation with human expertise effectively, businesses can assign AI to handle repetitive, high-volume tasks - such as creating purchase orders, forecasting demand, and tracking shipments - while leaving more complex or high-stakes decisions to human judgment. This approach helps streamline operations while ensuring that nuanced or exceptional cases are managed thoughtfully.

One practical way to achieve this balance is by implementing governance systems that monitor AI performance. These systems can detect issues like model drift and notify human teams when confidence levels drop, ensuring timely intervention. AI-generated insights should complement human decision-making, empowering supply chain managers to validate or refine actions based on market trends and strategic objectives.

Platforms like Leverage AI demonstrate how this integration works in practice. They automate tasks like supplier follow-ups and real-time tracking while offering intuitive dashboards and alerts for human oversight. This setup not only enhances operational efficiency but also maintains high standards of quality and control, keeping people at the heart of critical decision-making.

.png?width=50&height=50&name=julie-miller-square%20(1).png)