How to Track Supplier Portal Performance

%202%20(1).png?width=50&height=50&name=20250501_1415_Professional%20LinkedIn%20Update_remix_01jt6gxkjmekavnvzsewk61z9w%20(1)%202%20(1).png)

TL;DR: Tracking supplier portal performance ensures smooth supply chains and mitigates risks. Focus on measurable KPIs like on-time delivery, defect rates, and financial metrics. Use dashboards, automation, and AI tools to collect and analyze data in real time. Regular reviews and actionable insights strengthen supplier relationships and reduce disruptions.

Supplier performance impacts your bottom line. Missed deadlines or quality issues can cost millions annually, while effective tracking can boost efficiency and revenue. Start by defining clear KPIs, such as on-time delivery and cash-to-cash cycles. Integrate supplier portals with ERP systems for automated data collection and real-time monitoring. Use dashboards and scorecards for a clear view of performance trends, and leverage AI for predictive insights to prevent disruptions. Regular reviews ensure accountability and drive improvements.

How NetSuite Vendor Management Improves Supplier Relationships

Step 1: Identify Key Performance Indicators (KPIs)

KPIs turn supplier performance into clear, measurable data. They help establish accountability - not just for your vendors but also for your team. As Supply Chain Secrets aptly puts it:

"The real question isn't 'what can we measure?' It's 'what will we actually act on?'"

The trick is to focus on a few meaningful metrics rather than spreading your attention across dozens that may go unnoticed. When done right, effective KPI tracking can reduce costs by 20% and boost revenue by 6%.

Now, let’s break down how to define and set these KPIs for maximum impact.

Define Core KPIs

Start with metrics that directly influence operations. For example, on-time delivery measures reliability and is calculated as:

(Total orders - Late orders) ÷ Total orders × 100.

Another critical metric is ASN accuracy, which tracks how often Advanced Shipping Notifications match the actual shipment. This is essential for smooth warehouse operations.

Other operational KPIs include:

- Order fill rate: Tracks the percentage of orders successfully delivered in full on the first attempt.

- Defect rate: Monitors quality issues in delivered products.

- Portal usage metrics: Measures digital adoption, such as the percentage of processes automated through supplier portals.

Financial KPIs are equally important. The cash-to-cash cycle - calculated as Receivable days + Inventory days - Payable days - reveals how efficiently your supply chain moves capital. Industry leaders often achieve cycle times of less than a month.

Once you’ve identified these metrics, the next step is to set clear, actionable targets.

Set Measurable Targets

Defining KPIs is only half the battle. To make them actionable, you need precise benchmarks and clear goals.

Using the SMART formula ensures that targets are Specific, Measurable, Attainable, Realistic, and Time-Bound. For instance, you might aim to improve on-time delivery from 85% to 92% within six months, using industry benchmarks as a reference.

Here are some examples of benchmarks to guide your targets:

- Gross Margin Return on Investment (GMROI): A healthy range is between 200 and 225.

- Inventory velocity: Ideally, 60% to 70% for most items, with fast-moving products reaching up to 80%.

- Inventory turnover: Materials should move from warehouse to production within 30 days for optimal efficiency.

As Supply Chain Secrets warns:

"Measurement without consequence is pointless. If a supplier consistently underperforms against your KPIs and nothing changes in the relationship, your measurement programme is just administrative overhead."

To make your KPIs meaningful, tie them to real outcomes. Reward high-performing suppliers, and address underperformance promptly.

Step 2: Integrate Supplier Portals with Data Systems

After defining your KPIs, the next step is ensuring data flows smoothly and accurately. Manual data entry often slows things down, introduces errors, and leads to delays. Integration is the solution - it connects your supplier portal directly to your ERP system, creating a seamless flow of information.

The goal here is to establish a single source of truth. By integrating your systems, all supplier interactions are centralized into one record that updates automatically. This sets the stage for automating data collection, which we'll cover next.

Automate Data Collection

Automating data capture removes the need to manually transfer information between systems. For instance, your portal can automatically sync shipment details and compliance documents with your ERP.

This works by mapping supplier portal responses to your ERP's data fields. Say a supplier fills out a Request for Information (RFI) detailing their performance metrics - those responses can automatically populate User Defined Attributes (UDAs) in their supplier profile.

The benefits of automation are hard to ignore. Procurement teams often manage around 3,000 suppliers for every $1 billion in corporate spend. Without automation, keeping track of this many relationships can become overwhelming. Tools like strategic sourcing software with automated data collection can cut procurement costs by up to 9.8%.

Automation also enables real-time performance tracking. You can set up automated surveys, scorecards, and reminders to flag issues like quality problems or SLA breaches as they happen. By pulling data directly from work orders, invoices, and compliance logs, you’ll get a full picture of supplier performance without needing to chase down individual documents.

Use AI to Simplify Integration

AI can make the integration process much easier by connecting directly with your existing ERP system. This technology automates supplier follow-ups and offers real-time supply chain visibility.

To get started, ensure your ERP system is fully implemented. For example, if you're using Oracle Purchasing, make sure the core modules are licensed and operational. Once that's in place, you can set secure attributes (like ICX_SUPPLIER_ORG_ID and ICX_SUPPLIER_SITE_ID) to ensure suppliers can only access their own data. This keeps your system secure while enabling automatic data sharing.

AI-driven ERP integration can also feed performance data directly into dashboards and scorecards. This eliminates the need to dig through emails or hunt for documents, giving your team instant insights into which suppliers are meeting expectations and which need attention. Additionally, AI-powered automation takes care of routine tasks like document tracking and compliance monitoring, letting your team focus on building strategic supplier relationships instead of managing tedious details.

Step 3: Monitor Supplier Performance in Real Time

Once automated data collection is in place, the next step is to keep a close eye on supplier performance. Real-time monitoring helps you catch potential issues before they snowball. For example, you'll know immediately if a shipment is delayed, giving you time to act.

Here’s why this matters: 87% of procurement professionals rank managing supplier risk as their top priority. And for good reason - major supply chain disruptions can slash up to 62% of a company’s profits. Real-time dashboards are crucial for spotting risks early and preventing them from turning into full-blown crises.

Set Up Real-Time Dashboards

To make the most of your data, start by creating a dashboard that provides a clear view of key metrics. Focus on selecting the right KPIs - think inventory visibility, on-time delivery rates, or supplier watchlists. These metrics should be directly linked to your ERP system, ensuring the data is always up-to-date and accurate.

Keep things simple by limiting your dashboard to 5–10 KPIs. Each metric should have a clear purpose and lead to actionable insights. For example, if you notice the Customer Order Cycle Time (the average time between order placement and shipping) is increasing, it’s a clear signal to investigate potential bottlenecks.

You can also use weighted categories to calculate an overall supplier score. For instance, you might assign weights like 40% to Quality, 30% to Delivery, and 20% to Cost, creating a single performance rating that’s easy to interpret. Adding hover-over details for deeper insights can make drill-down analysis faster and more intuitive.

Before launching your dashboard, establish baselines using historical data. This step ensures you can properly evaluate current performance. For example, is a 95% on-time delivery rate excellent, or does it signal a decline? Historical benchmarks provide the context needed to answer that question.

Use Supplier Scorecards

Dashboards are great for real-time updates, but scorecards offer a broader, long-term view of supplier performance. Think of them as report cards that assess how well a supplier meets your expectations across multiple areas.

"Supplier scorecards solve these challenges by providing a structured framework to measure, track, and analyze vendor performance across standardized metrics, enabling procurement professionals to make data-driven decisions." – Chris Sumida, Group Manager of Product Marketing, Ramp

Scorecards often use a 1–5 scale for qualitative metrics, making it easier to compare suppliers. For example, you might evaluate factors like responsiveness, communication quality, and flexibility. Combine these qualitative scores with hard data, such as defect rates or invoice accuracy, to get a complete picture.

Create two versions of the scorecard: a detailed internal one for your team and a summarized version to share with suppliers. Sharing performance ratings encourages suppliers to address issues proactively when their scores dip.

For even deeper insights, integrate financial risk data into your scorecards. Tools like Dun & Bradstreet Credit Scores (rated 0–100, with higher scores indicating lower risk) or Supplier Evaluation Risk Scores (on a 1–9 scale) can alert you to financial instability, even if a supplier’s operational metrics seem solid.

Here’s the payoff: Procurement teams using modern tracking tools report three times faster cycle times and 69% less manual effort. Centralizing performance data and automating updates eliminates the chaos of scattered spreadsheets and email chains, making your entire process more efficient.

sbb-itb-b077dd9

Step 4: Analyze Trends and Generate Reports

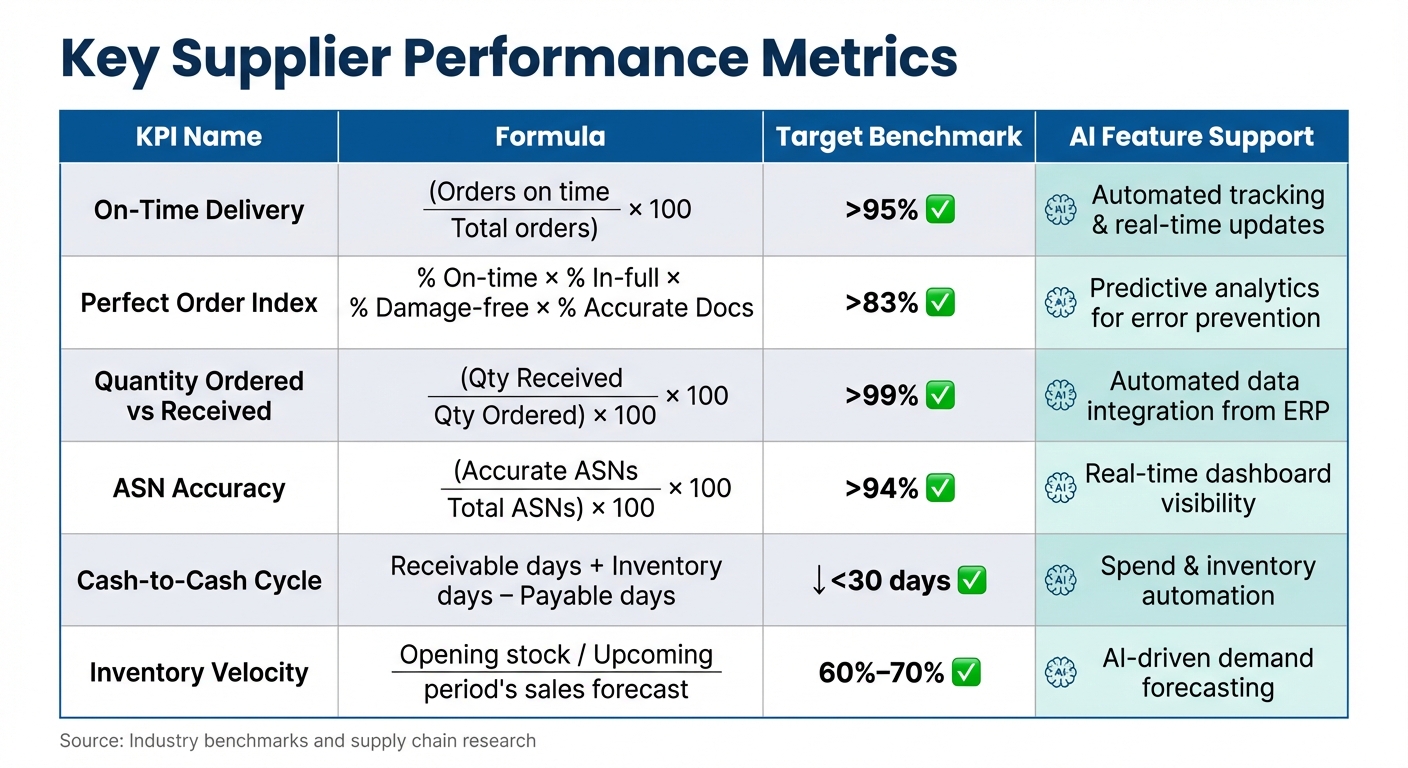

Key Supplier Performance KPIs: Formulas, Benchmarks, and AI Support

Turning raw data into actionable insights is where the real value lies. Collecting metrics is just the first step - analyzing patterns over time and generating reports completes the process. According to recent findings, 79% of companies with top-performing supply chains experience above-average revenue growth, compared to only 8% of those with weaker operations. This shows that effective trend analysis can set industry leaders apart by identifying performance gaps and guiding strategic improvements.

Review Performance Trends

Start by monitoring supplier performance over specific periods, such as monthly or quarterly. This method helps uncover patterns in supplier behavior and operational reliability. For instance, if a supplier's on-time delivery rate slips from 96% to 88% over three months, it’s a clear indicator that something has shifted.

Focus on 5–10 key performance indicators (KPIs) that align with your business goals to spot shifts and investigate their causes. Let’s say you notice a decline in performance - maybe the supplier switched to a cheaper logistics provider or altered their raw material sourcing. Digging into these root causes transforms raw data into meaningful insights.

Also, consider how different metrics interact. For example, a supplier might cut costs, but if product quality declines as a result, that trade-off can have significant consequences. Understanding these interdependencies provides a more complete view of your supply chain’s overall health.

Use Data for Actionable Insights

Once you’ve identified trends, calculate specific metrics to uncover performance gaps. Take the Perfect Order Index as an example: it multiplies rates for On-Time, In-Full, Damage-Free, and Accurate Documentation deliveries. Even if individual rates are high (e.g., 92% on-time and 95% in-full), the combined score can drop to 83%. This unified metric reveals the true rate of error-free deliveries.

It’s also helpful to separate "advised" shortages (communicated beforehand) from "unadvised" ones (discovered upon receipt) to better understand disruptions. Including these distinctions in your reports sharpens the insights you gain.

"Measurement without consequence is pointless. If a supplier consistently underperforms against your KPIs and nothing changes in the relationship, your measurement programme is just administrative overhead." – Supply Chain Secrets

Use these reports to drive change. For example, offer better payment terms to top-performing suppliers or reduce orders for those who consistently underperform. Optimizing digital supply chains can lower operational costs by up to 20% and increase revenue by as much as 6% - but only if you act on the insights.

KPI Comparison Table

Here’s a quick reference for key supplier metrics and how AI tools can enhance their tracking:

| KPI Name | Formula | Target Benchmark | Leverage AI Feature Support |

|---|---|---|---|

| On-Time Delivery | (Orders on time / Total orders) × 100 | >95% | Automated tracking & real-time updates |

| Perfect Order Index | % On-time × % In-full × % Damage-free × % Accurate Docs | >83% | Predictive analytics for error prevention |

| Quantity Ordered vs Received | (Qty Received / Qty Ordered) × 100 | >99% | Automated data integration from ERP |

| ASN Accuracy | (Accurate ASNs / Total ASNs) × 100 | >94% | Real-time dashboard visibility |

| Cash-to-Cash Cycle | Receivable days + Inventory days – Payable days | <30 days | Spend & inventory automation |

| Inventory Velocity | Opening stock / Upcoming period's sales forecast | 60%–70% | AI-driven demand forecasting |

Efficient companies often maintain cash-to-cash cycles of under 30 days. Additionally, a strong Gross Margin Return on Investment (GMROI) typically falls between 200 and 225. By using these benchmarks, you can evaluate supplier performance and pinpoint areas for improvement. Each KPI in the table ties directly to insights gained from analyzing trends, helping you make smarter, data-driven decisions in managing your suppliers.

Step 5: Implement AI for Predictive Analytics

AI takes supplier portal tracking to the next level by shifting from reactive management to proactive strategies. Instead of waiting to address issues after they’ve disrupted operations, predictive analytics helps spot potential problems before they escalate. This is a game-changer - supply chain disruptions can slash as much as 62% of a company’s profits. By combining historical data with predictive tools, businesses can take action ahead of time.

AI-Driven Predictive Insights

AI excels at analyzing massive datasets to uncover patterns that might go unnoticed by human analysts. For instance, risk-sensing platforms merge external disruption signals - like weather forecasts, geopolitical events, or market trends - with supplier performance data. This integration allows for automated simulations and impact analyses. Imagine a scenario where severe weather threatens a key supplier’s region. The system can instantly evaluate which purchase orders are at risk and recommend alternative sourcing options.

Tools like digital twins add another layer of insight by creating visual models of potential disruptions. These simulations help pinpoint high-risk suppliers and guide decisions on how to mitigate those risks effectively. However, before rolling out AI algorithms, it’s crucial to clean up historical data to avoid biased results. Start with a prioritized roadmap that tackles your most urgent supply chain challenges.

"In the race for supply chain excellence, intelligence is the fuel. Win with IQ, power with AI. The future is not waiting. It's being built now." – ZS

Strengthening Supplier Relationships with AI

AI doesn’t just predict disruptions - it also improves everyday supplier interactions. Automation tools enhance communication and streamline processes, making supplier relationships more efficient. Platforms like Leverage AI handle routine tasks such as shipment status checks and stock verification. By reducing errors and automating follow-ups, your team can focus on strategic decisions instead of getting bogged down by administrative work.

These automated systems also foster transparency by offering a shared "single source of truth" accessible to both you and your suppliers. Real-time feedback replaces the traditional quarterly review cycle, turning supplier relationships into collaborative partnerships. This approach pays off - companies that nurture strong, collaborative supplier relationships grow at twice the rate of those that don’t. That said, while AI can streamline processes, it’s no substitute for the human touch. Building trust and maintaining personal connections remain essential.

Step 6: Review and Act on Performance Insights

Tracking supplier performance only matters if the insights lead to meaningful action. The goal here is to turn evaluations into opportunities for collaboration, promoting transparency and stronger partnerships. This step builds on the automated tracking and real-time insights discussed earlier.

Conduct Regular Supplier Reviews

Not all suppliers need the same level of attention, so segment them to determine how often reviews should happen. For example, critical suppliers - those handling the bulk of your procurement budget - might require monthly or quarterly reviews. On the other hand, low-risk vendors can be reviewed annually.

There are two main types of reviews to consider:

- Monthly Operational Reviews (60 minutes): These focus on immediate issues like late deliveries, quality problems, or unresolved corrective actions.

- Quarterly Business Reviews (90–120 minutes): These take a step back to look at broader trends, such as year-to-date performance, cost fluctuations, innovation opportunities, and decisions about how much business to allocate to a supplier.

Using standardized scorecards is a must. These scorecards should consolidate both monthly and trailing-12-month data, creating a reliable reference point for everyone involved.

"Evaluating supplier performance isn't just paperwork - it's about building a supply chain that helps your business thrive." – Richard Teuchler, Head of Demand Generation, Kodiak Hub

Keep your focus tight by monitoring 5–10 key performance indicators (KPIs) that directly influence decision-making. Metrics that don’t drive action should be eliminated. Document all findings in a Corrective and Preventive Actions (CAPA) register, ensuring each issue has an assigned owner, a deadline, and clear steps for resolution.

Here’s a quick summary of review frequencies based on supplier categories:

| Supplier Category | Review Frequency | Primary Focus |

|---|---|---|

| Critical Suppliers | Monthly or Quarterly | Real-time issues, delivery, quality, risk management |

| Strategic Partners | Quarterly (Deep dive annually) | Long-term planning, innovation, joint development |

| Standard Suppliers | Bi-annually or Annually | Quality, delivery accuracy, price compliance |

| Low-Risk Suppliers | Annually | Basic metrics, contract adherence |

Adjust Strategies Based on Data

Your KPIs should guide how you adapt your strategies. When a supplier consistently meets or exceeds expectations, it’s worth rewarding them - perhaps with a larger share of business or a long-term partnership. For those falling short, work together to uncover the root causes. Sometimes, issues stem from your own processes, like unclear ordering systems, or the supplier may need additional training to meet your quality standards.

If collaboration doesn’t lead to improvement, the data will support decisions to reduce their business share or even phase them out entirely. Companies that prioritize supplier collaboration grow at twice the rate of those that don’t. So, make these reviews count - your supply chain’s success depends on it.

Conclusion

Tracking supplier portal performance turns raw data into practical insights that can strengthen your supply chain. To get started, focus on these key steps: identify 5–10 core KPIs that directly influence your business, integrate supplier portals to ensure smooth data flow, and set up real-time dashboards to spot and address issues before they grow into bigger problems.

Once the basics are in place, AI-powered tools can take your tracking to the next level. These tools can automate tasks like extracting purchase order details, simplifying supplier acknowledgment workflows, and providing a centralized view of critical metrics like on-time delivery and quality performance. Moving from manual tracking to automated systems not only reduces errors but also frees up your team to focus on strategic decisions that drive growth.

Consider this: companies that collaborate effectively with their suppliers grow twice as fast. On the flip side, poor supplier data management can cost businesses an average of $15 million annually, and 87% of procurement professionals see managing supplier risk as their top priority. These numbers make it clear - relying on outdated spreadsheets or gut instincts is no longer an option.

"The point isn't just measurement. It's making things better." – esgrid.com

This quote underscores the importance of taking action based on the insights you gather.

Supplier evaluation isn’t a one-and-done task - it’s an ongoing process. Regular reviews, automated alerts, and adjusting KPIs as your business evolves ensure your tracking system stays relevant. When you use performance insights to drive meaningful conversations with suppliers - whether to reward top performers with more opportunities or to address issues with underperformers - you create partnerships that promote mutual success. This proactive approach not only strengthens relationships but also helps safeguard your business against disruptions that could cut profits by as much as 62%. By turning data into decisive actions, you lay the groundwork for growth and resilience.

FAQs

What are the key KPIs to measure supplier performance effectively?

To keep tabs on how well your suppliers are performing, pay attention to these key performance indicators (KPIs):

- On-time delivery rate: This tracks the percentage of orders suppliers deliver within the agreed-upon timeframe. Timely deliveries keep your operations running smoothly.

- Quality or defect rate: Measures how often you receive defective or non-conforming products. Fewer defects mean higher reliability.

- Cost variance: Compares the agreed cost of goods or services to what you actually end up paying. Keeping this in check ensures budgets stay on track.

- Order accuracy: Evaluates how closely the delivered quantity matches what you originally ordered. Mistakes here can lead to delays or overstocking.

- Compliance and risk score: Assesses how well suppliers follow regulatory standards and manage risks. This reduces potential liabilities for your business.

Regularly monitoring these KPIs helps you spot patterns, strengthen supplier partnerships, and avoid disruptions in your supply chain.

How can AI improve the way you monitor supplier portal performance?

AI has the potential to revolutionize how supplier portal performance is monitored. By automating data collection, it provides real-time insights and even predicts possible delays. With AI-driven dashboards and integrated scorecards, you can keep a close eye on supplier performance and tackle problems before they grow into bigger issues.

Integrating these tools directly into your ERP system offers a centralized view of all supplier activities. This streamlines communication, enhances collaboration, and speeds up decision-making. For manufacturers and distributors, this means staying ahead of supply chain hurdles with greater efficiency.

What should I do if a supplier isn’t meeting performance expectations?

If a supplier isn’t meeting expectations, the first step is to evaluate their performance using supplier scorecards. These tools can pinpoint the exact areas where they’re underperforming. Once you’ve identified the issues, share this feedback right away and work together to develop a corrective action plan with specific, measurable goals.

Keep an eye on their progress and offer ongoing support to help them get back on track. However, if the problems continue despite these efforts, you may need to enforce any agreed-upon penalties or even switch to a more dependable supplier. Open communication and consistent follow-ups are crucial for addressing these issues effectively.

%202%20(1).png?width=50&height=50&name=20250501_1415_Professional%20LinkedIn%20Update_remix_01jt6gxkjmekavnvzsewk61z9w%20(1)%202%20(1).png)